Production Order - Process Manufacturing Report

The Production Order - Process Manufacturing report prints a list of the work in progress or finished production order information including:

- Routings

- Components

- Components with expected and remaining quantity for released and finished production orders

- Ingredients

- Item tracking lines

- Assigned COSMO Planning Extension resources

- COSMO Text Module lines (either assigned directly to the production order component or assigned to the originating production structure line)

This report is accessible:

- for batch processing:

- Tell Me feature by entering Prod. Order - Process Manufacturing

- Production Planner PM and Manufacturing Manager Role Centers by choosing Prod. Order - Process Manufacturing on the Production menu within the Actions part

- for individual production orders, choose Print > Prod. Order - Process Manufacturing on the Actions menu of the following pages:

- Planned Production Orders/Planned Production Order

- Firm Planned Prod. Orders/Firm Planned Prod. Order

- Released Production Orders/Released Production Order

- Finished Production Orders/Finished Production Order

In the report request page, you can choose if and how line text is printed in the report. The fields are described in the following table.

| Field | Description |

|---|---|

| Print Line Texts | Determines whether line text is printed or not. |

| Print Line Texts from Production Structure | Determine if production order component line text is printed (toggle off) or if production structure line text is printed (toggle on). |

Planned and Firm Planned Production Orders

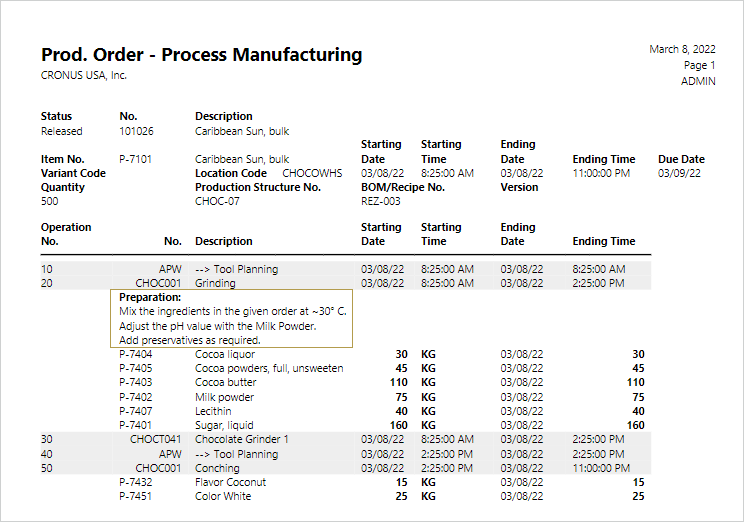

The planned and firm planned production orders show general production order information in the header, such as item, quantity, location, starting/ending date/time, production structure and BOM/recipe numbers.

The lines show routings and components with quantities, starting/ending dates/times. If selected in the report request page, line text for production structure or production order lines is shown.

Released Production Orders

The report for the released production order without posting is the same as the planned and firm planned production order.

The following graphic shows the Prod. Order - Process Manufacturing report for a released production order with no posting. Line text added to a production order routing is highlighted in gold.

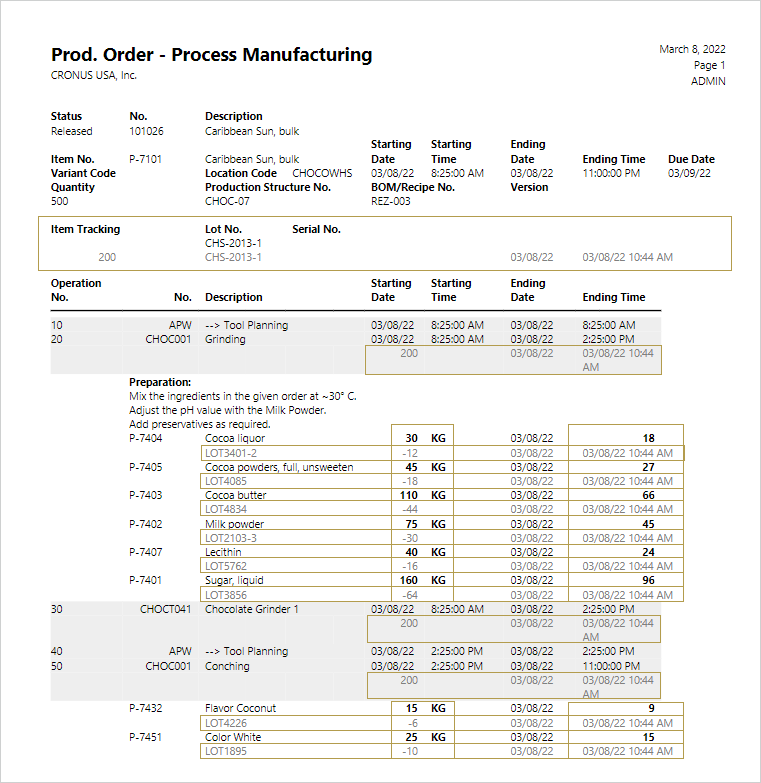

Once posting occurs, the report also shows the following:

- in the header

- Output Item Ledger Entries with the posted quantity and the lot-/serial number, posting date, creation date and time

- in the lines

- Capacity Ledger Entries with the output quantity, posting date, creation date and time

- Consumption Item Ledger Entries with the consumed quantity and lot-/serial number, posting date, creation date and time

- Component lines include the planned total quantity (bolded) and then the remaining quantity (bolded)

The following graphic shows the Prod. Order - Process Manufacturing report for a released production order with partial posting. Differences from the previous graphic due to posting are highlighted in gold.

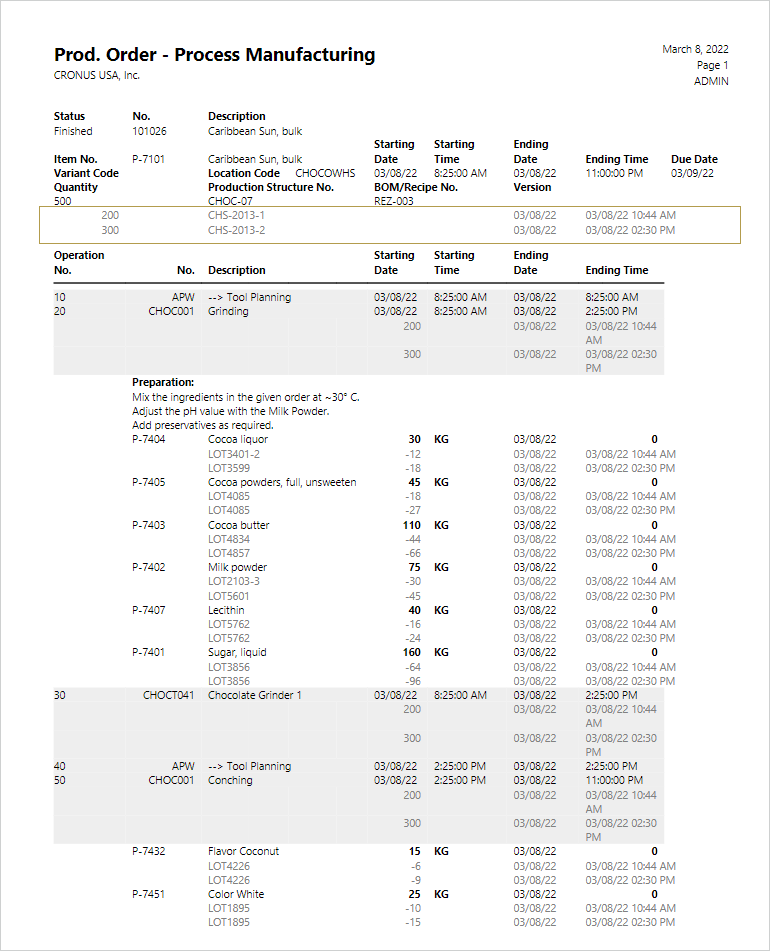

Finished Production Orders

The report for the finished production order shows the same information as the released production order with postings except a minor difference in the header.

The following graphic shows the Prod. Order - Process Manufacturing report for a finished production order with complete posting; therefore, additional output and consumption postings are included. The difference between the report for the fully posted released production order and finished production order is highlighted in gold.

Feedback

Submit feedback for this page .