COSMO Discrete Manufacturing

Built to enhance Microsoft Dynamics 365 Business Central with industry-specific functionality, COSMO CONSULT offers an industry-specific solution with COSMO Discrete Manufacturing that integrates all operational procedures of production planning and control into the business processes of companies in countless industrial sectors such as, mechanical and plant engineering, special vehicle construction, lift manufacturing, as well as equipment and apparatus engineering.

Traditionally sold as an independent solution with exclusive integrated add-on modules, COSMO Discrete Manufacturing offers a packaged set of functionality that delivers particular support for handling the fabrication and assembly steps needed by discrete and lean manufacturers and providing the requirements demanded by highly regulated environments.

COSMO Discrete Manufacturing relies on a unique, integrated information system guaranteeing consistent and transparent management of all business data at all times through industry specific functionalities such as, immediate and simultaneous calculations or the product configuration using dynamic bills of material (BOMs). This allows a quick realization of important company objectives in terms of transparency and stability of processes, optimization of results in production planning, as well as the reduction of lead times.

Key Features

- Checklist system

- Dynamic bills of material

- Document schedule plan

- Document bill of material

- Construction

- Production accompanying construction

- Calculation schemes

- Supply material for outsourced production

- Preliminary orders for long-running transactions

- Exchange of materials and groups

- Service processes

- Discontinued items

- Prototypes

- Item description catalog

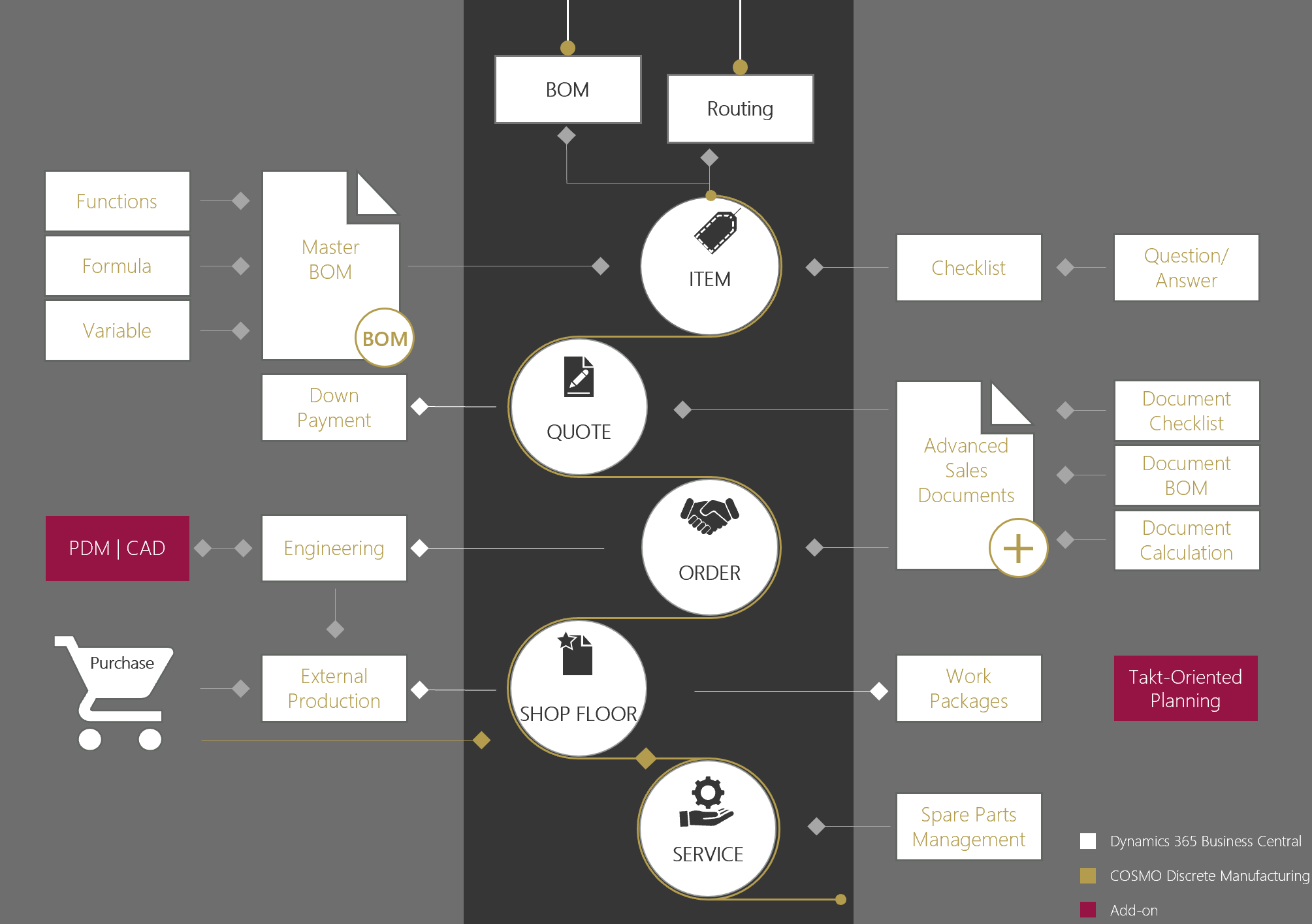

COSMO Discrete Manufacturing contains an extensive structure of many connected components, as the following graphic illustrates.

The item master can become a master BOM and checklists can be assigned to it. Formulas, functions, and variables assigned in the master BOM and checklist work together to form a configuration, which is used to produce a BOM. The checklists are populated in the quote, order, and/or the construction order by answering pre-defined questions.

During the quoting process, the item-assigned checklist is copied to the sales line (Document Checklists). After completing the Document Checklist, the Master BOM can be interpreted and copied to the sales line (Document BOM). Both checklists and Document BOMs can be changed on the orders.

Afterwards, a construction order is generated from a sales order. The construction order is a copy of the BOM for the order (Document BOM). The construction order can be changed and modified by the engineering department. After technical review of the construction order, a production order is generated (this can come also from the sales order).

During MRP – using the planning worksheets or the order planning functionality – requisitions for the order can be created. This happens either at the time of manufacturing, construction, or from the sales order.

Access COSMO Discrete Manufacturing functionality using the Tell Me feature in Microsoft Dynamics 365 Business Central. Choose the  icon, enter the page name, and then choose the related link.

icon, enter the page name, and then choose the related link.

Feedback

Submit feedback for this page .