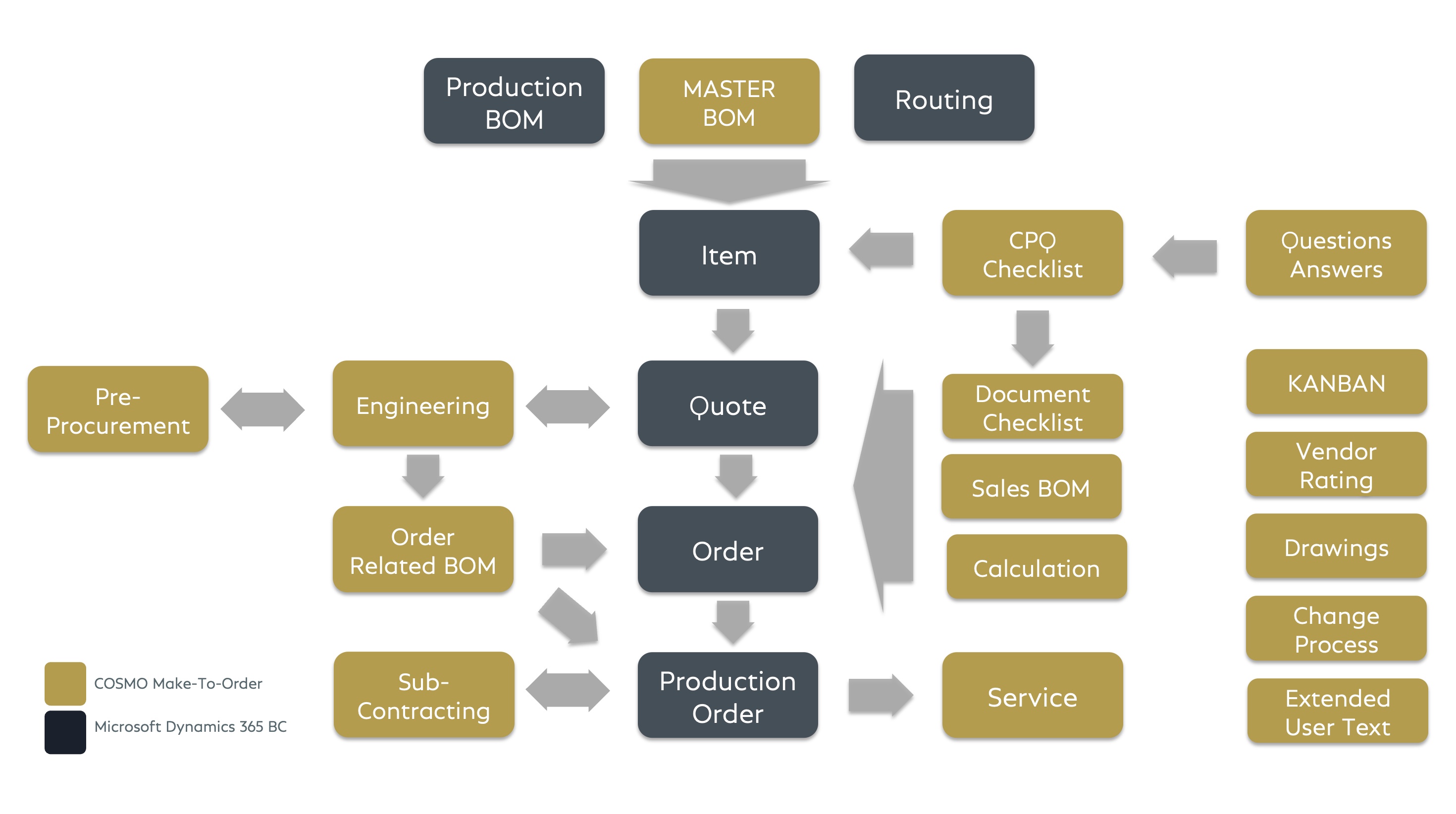

COSMO Make-to-Order

Our implementation package designed specifically for make-to-order manufacturers is tailored to enhance core processes, boosting efficiency where it's needed the most.

Leverage the capabilities of COSMO Make-to-Order within Microsoft Dynamics 365 Business Central to elevate manufacturing business.

Sales Processes - Several features are available within the sale process which include:

- Structured order specifications

- Permanent assignment

- Cloud based accessibility at any time

- Accuracy checks

- Pricing options

- Sales BOM creation for pre-calculation

- Pre, concurrent, and post-calculation with a flexible costing template and formula editor

Engineering - Processes can be monitored through integrated change management. These include:

- Manage technical BOMs, design changes, and item replacements in their work environment

- Prototype creation ensures quality control

- Drawings and revision tracebility

- Cross-divisional change management

Shop Floor

- Offers extended sub-contracting including outsourced work steps

- Material supply options for sub-contractors

- Visual production planning to identify bottlenecks,

- Real-time planning, component planning and inventory availability check

Service

- Upgraded service BOMs to document the status of a machine.

- In-house repair process to manage repairs of a service item or a component.

- Simplified spare part sales.

Warehouse

- The KANBAN method uses visual elements to signal low inventory and time to restock. Discrete manufacturing and shipping are managed flexibly without the need for complex MRP. Often, the deliveries in discrete manufacturing are very large and cannot be shipped altogether for final assembly on site. The “Separate Delivery” function allows the assembly to be defined and delivered within a desired timeframe.

Master Data - The Master BOM integrates a traditional BOM with routing, offering a multi-level view of the entire product structure, and can be tailored for sales, design, service, among other applications.

User Instructions - The system integrates extended user instructions across all stages, from sales to production, allowing storage of text, images, and QR codes. It includes real-time updates and AI-assisted text formulation with a versatile text editor.

Quality Assurance - The ERP allows manual/automatic test orders across the supply chain, ensuring raw material/product quality.

Focused Industries

- Device Manufacturing

- Gouvernance

- Machine Construction

- Vehicle Manufacturing