Sequence Planning

Sequence Planning is a main function of COSMO Process Manufacturing. The entire manufacturing process can be controlled in the Sequence Planning page, including the recognition of shortages of resources or materials, detailed planning and production order feedback.

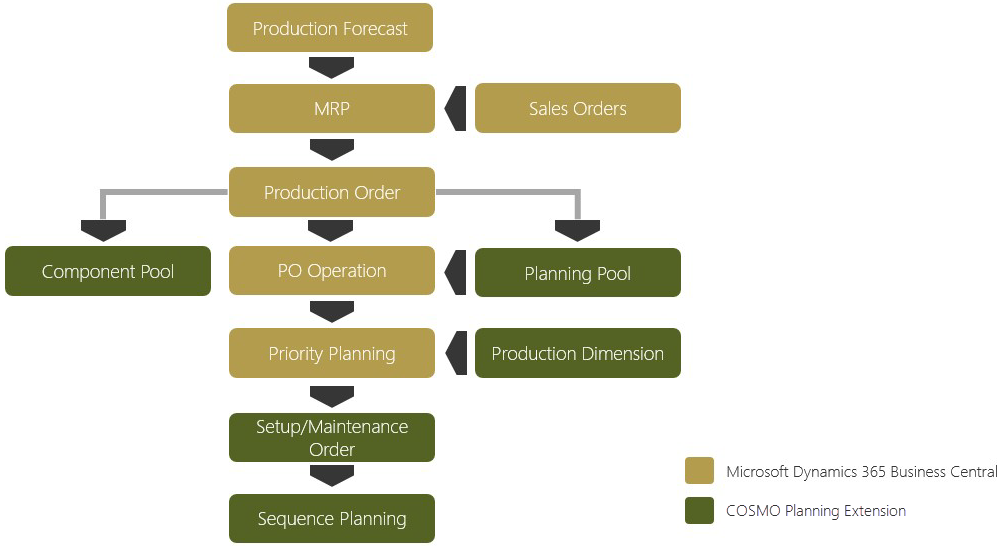

The integration of sequence planning in COSMO Process Manufacturing with Microsoft Dynamics 365 Business Central contains an extensive structure of many connected components, as the following graphic illustrates.

The following table describes a sequence of tasks, with links to the topics that describe them.

| To | See |

|---|---|

| Learn about the fields and actions on the Sequence Planning page. | Sequence Planning Page |

| Fix production orders in the sequence planning so that the current calculated start and end dates are not changed during the sequence planning process. | Fixed in Sequence Planning |

| Defer production order lines in sequence planning permanently so that the re-scheduling process does not consider the production order line. | Permanently Deferred in Sequence Planning |

| Use the sales planning function to direct the production based on a desired delivery date. | Scheduling on Due Date in Sequence Planning |

| Prevent the automatic rescheduling of sequence work centers and attached production orders when changes are made. | Manual Rescheduling of Sequence Planning |

| Learn how to automatically set the Planning Flexibility field to None in sequence planned production order lines. | Planning Flexibility in Sequence Planning |

| View overload of work center or machine center/overlapping of tools or inserts. | Visualize Capacity Currently Utilized on Work Centers/Tools |

| Allow the creation of a warehouse pick for production order lines reversed in Sequence Planning. | Allow Picking for Prod. Order Lines Reversed in Sequence Planning |

| Perform sequence planning using a visualized planning tool. | Graphical Sequence Planning |

Feedback

Submit feedback for this page .