Fixed Step Production Rate Time

With fixed-step production rates, the production rate time remains constant on certain intervals of the production rate quantity. Fixed-step production rates are used when resources have a maximum capacity but use a fixed time to run a process.

Example 1: A mixer has a maximum volume of 500 kg and is used for one 30-minute process. Regardless if you have 250 kg or 490 kg to mix, the mixer uses the same time to finish the work.

Example 2: A dryer used 45 minutes for the drying process. Because of the maximum capacity, the dryer only has room for 300 cubic meters of products.

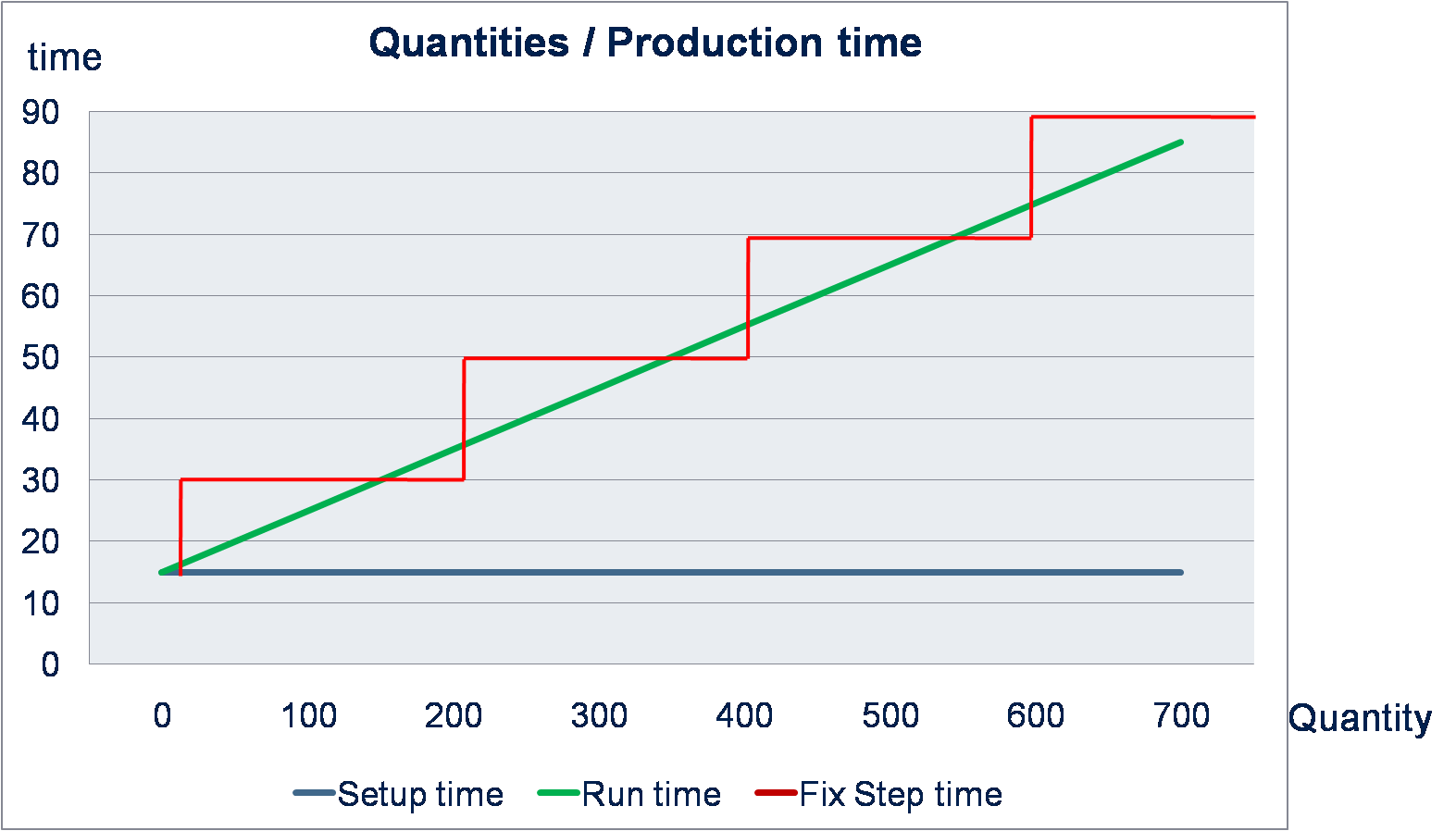

The following graph explains how fixed step production rates are used.

As illustrated, each line in the graph represents a production time:

- The blue line (bottom) is the setup time, which requires a machine, whether 1 piece or 1000 pieces are produced; this time is not changed.

- The green line (diagonal) is the normal course of a production with throughput calculation or mass per unit calculation. The more units produced, the more time is needed for production.

- The red line is the fixed step time. In a quantity of 0 to 200, the lead time is always the same, regardless if 10 or 150 are produced, the time is always 30. For the next quantity range of 200 to 400, the time increases to 50 and so on.

Fixed Step Production Rate Time Setup

In the Work Center Prod. Rate Card page, use the Fixed-Step Prod. Rate Time toggle to lock in the production rate time.

For example, 1500 pieces of an item are produced for a period of 60 minutes, namely:

- 0 – 1500 PCS = 60 minutes

- 1501 – 3000 PCS = 120 minutes

- 3001 – 4500 PCS = 180 minutes and so on

When a production order is calculated, the setup time and run time are calculated for each quantity step defined in the Production Rate field, regardless of the exact production order quantity.

In the routing, you can see if an operation has a Fixed-Step Prod. Rate Time and the assigned Fixed-Step Production Rate.

Comments, Tools, Personnel, and Quality Measures

Comments, Tools, Personnel, and Quality Measures can be added to Work Center Production Rates and then copied to the related production order routing line if a work center production rate is used for a production order line, for example by production order calculation or work center change in Sequence Planning. On the Work Center Prod. Rate Card page, these settings can be manually entered using actions on the Related menu.

Alternatively, Standard Tasks (accessed using Tell Me) can be created with these settings and then assigned to the Standard Task Code field on the Work Center Prod. Rate Card page.

Note

The Standard Tasks page is the same as the Work Center Production Rates Card except comments are entered using the Description action. The description text transfers to the Comment Sheet on the routing line.

Once the settings have been assigned to the production rate, each is automatically transferred to the production order routing line. These settings are overwritten if the work center is changed to one that has different settings or removed if changed to one that has no settings.

If a routing line has been changed from a work center with no production rate to one with production rates, and then changed back to the originating work center, the routing information (setup and run time, comments, tools, personnel, and quality measures) are also reverted to the original value in Sequence Planning.

See Also

Work Center Production Rates

Sequence Planning

Feedback

Submit feedback for this page .