Task-Based Scheduling - Setup

The general setup of the module is required in several places in the system.

The setup pages are accessed using Tell Me.

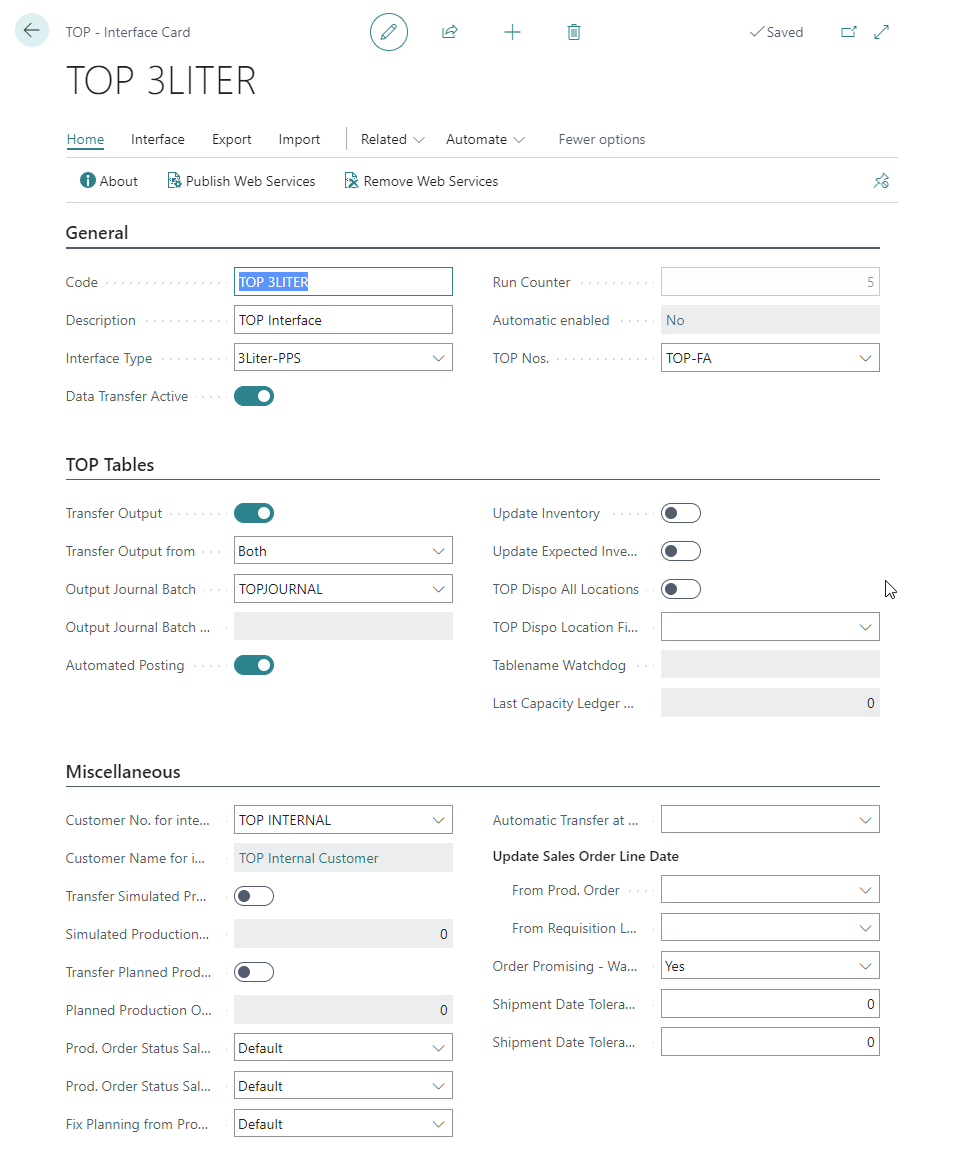

TOP - Interface Card

Choose the  icon, enter TOP - Interface List, and then choose the related link.

Choose New and create a new TOP - Interface Card. The specifications can be made in the card.

icon, enter TOP - Interface List, and then choose the related link.

Choose New and create a new TOP - Interface Card. The specifications can be made in the card.

General FastTab

| Field | Description |

|---|---|

| Code | Unique identifier of the interface definition (max. 20 characters). |

| Description | Description of the interface definition. |

| Interface Type | The external PPS that is to be connected can be specified here. Currently, only the 3Liter PPS® is available. |

| Data Transfer Active | Controls whether this interface definition may be used. |

| Run Counter | Specifies how often the interface processing has been performed (non-editable). |

| Automatic enabled | Specifies whether automatic data processing is active (not editable), see Data Transfer. |

| TOP Nos. | In Standard Microsoft Dynamics 365 Business Central, a separate number series can be stored for each production order status. In the external PPS, however, a production order must retain a number that has been assigned once so that it can be referenced again and again (even when the status changes). For this reason, a general number series for production orders can be stored here, which is then used for all production orders in Microsoft Dynamics 365 Business Central, regardless of their status. |

TOP Tables FastTab

| Field | Description |

|---|---|

| Transfer Output | Specifies whether transfer output should be transferred between the two systems. |

| Transfer Output from | Specifies from which system the output will be transferred (Microsoft Dynamics 365 Business Central, External PPS, Both). |

| Output Journal Batch | Specification of an output journal in which the output imported from the external PPS is inserted. |

| Output Journal Batch Description | Display of the description of the above mentioned journal name (not editable). |

| Automated Posting | Specifies whether the output imported from the external PPS is to be posted automatically. If this option is not activated, the output is only entered in the above-mentioned journal and must then be posted manually. |

| Update Inventory | Specifies whether inventory information of Microsoft Dynamics 365 Business Central are transferred to the external PPS. This might be needed for the use of material planning in the external PPS. |

| Update Expected Inventory Changes | Activates the transferring of expected Inventory changes. |

| TOP Dispo All Locations | Here you can define whether the inventories of all warehouses are to be taken into account when transferring inventory information. |

| TOP Dispo Location Filter | If not all warehouses are to be included in the inventory transfer (see above), a storage location filter can be defined here for determining the inventory information. |

| Tablename Watchdog | Here it is intended to store a table with the help of which the availability of the interface can be checked. This function is currently not available and, therefore, the field is not editable. |

| Last Capacity Ledger Entry No. | Specifies the last used capacity ledger entry (= output) of Microsoft Dynamics 365 Business Central which has been transferred to the external PPS (not editable). |

Miscellaneous FastTab

| Field | Description |

|---|---|

| Customer No. for internal Prod. Orders | In the currently connected external PPS, only orders with a customer number can be processed. The customer number stored here is used for production orders without any related customer order (make-to-stock production). |

| Customer Name for internal Prod. Orders | Shows the customer name to the above customer number (not editable). |

| Transfer Simulated Production Orders | Specifies if it is possible to transfer production orders with the Simulated status to the external PPS. |

| Simulated Production Order Expiration Time (days) | Specifies how long (in days) planning for transferred productions orders with the Simulated status is to be retained in the external PPS. After this period the planning for production orders with the Simulated status will be removed from the external PPS. |

| Transfer Planned Production Orders | Specifies if it is possible to transfer production orders with the Planned status to the external PPS. |

| Planned Production Order Expiration Time (days) | Specifies how long (in days) planning for transferred production orders with the Planned status is to be retained in the external PPS. After this period the planning for production orders with the Planned status will be removed from the external PPS. |

| Prod. Order Status Sales Quote | The Status for created Prod. Orders from Order Promising Function from Sales Quotes (Standard = Simulated). |

| Prod. Order Status Sales Order | The Status for created Prod. Orders from Order Promising Function from Sales Orders (Standard = Planned). |

| Fix Planning from Status | The status from which the production order planning should be fixed (set planning flexibility to None). |

| Automatic Transfer at Calculation Prod. Order | Controls in which cases a production order is automatically transferred to the external PPS after recalculating (see Data Transfer) (Sales order – After creating a production order from a sales order, Manually – when manually calling the recalculation of a production order, Both). |

| Update Sales Order Line Date | Group |

| From Prod. Order | Specifies the Date Field in Sales Line, which is automatically set, if Production Order Due Date is changed from Interface. |

| From Requisition Line | Specifies the Date Field in Sales Line, which is automatically set, if Requisition Line Due Date is changed from Interface. |

| Order Promising - Waiting for planning result | Specifies whether to wait for the planning result when the order promising is executed. |

| Shipment Date Tolerance for Order Promising | Defines the tolerance for exceeding the desired delivery date of a quotation or order when using the Order Promising function. |

| Shipment Date Tolerance for Production Orders | Defines the tolerance for exceeding the due date of a production order. Is inherited from the setup to the production order, but can be changed there again. |

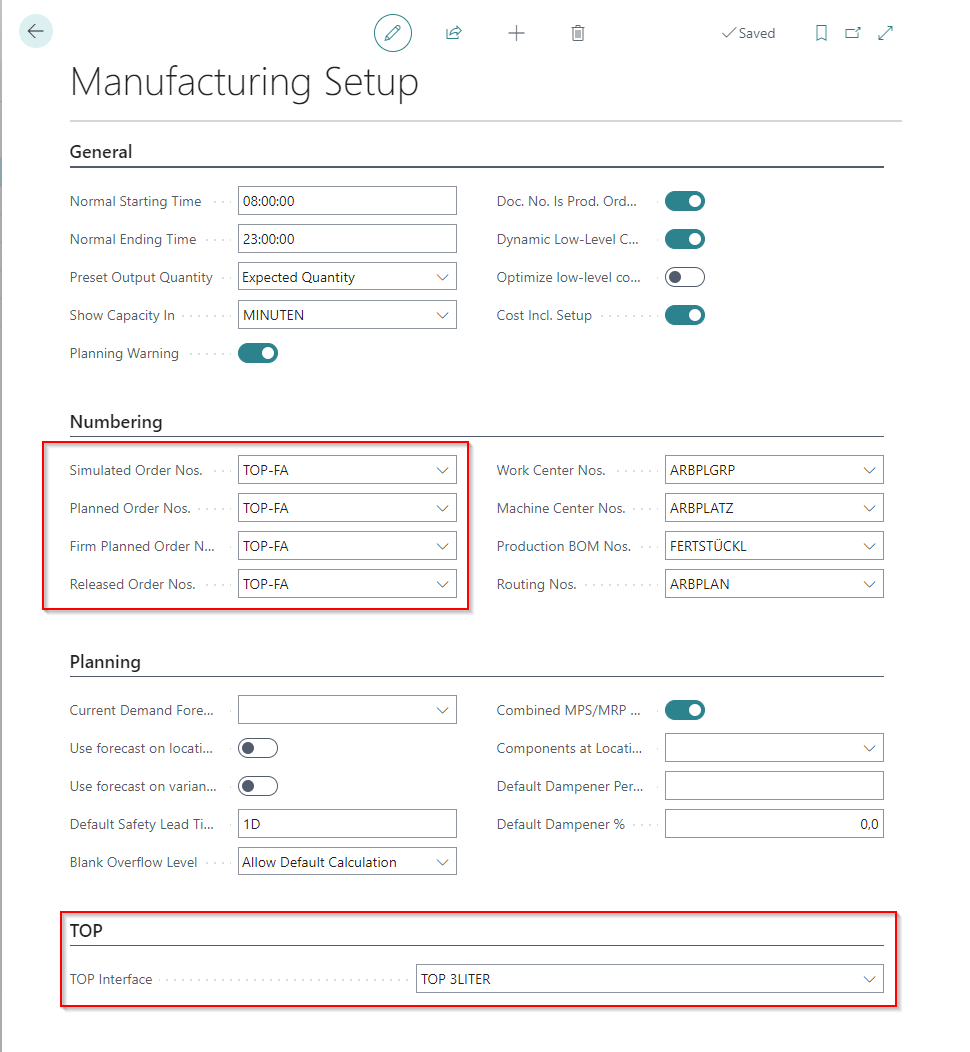

Manufacturing Setup

Choose the  icon, enter Manufacturing Setup, and then choose the related link.

icon, enter Manufacturing Setup, and then choose the related link.

The fields indicated in 1 (see screen shot) are automatically updated with validation of the TOP number series in the TOP interface.

In 2 (see screen shot), the TOP interface to be used (from 1.) is to be stored. Several interface definitions can be created, only one can be selected in the setup.

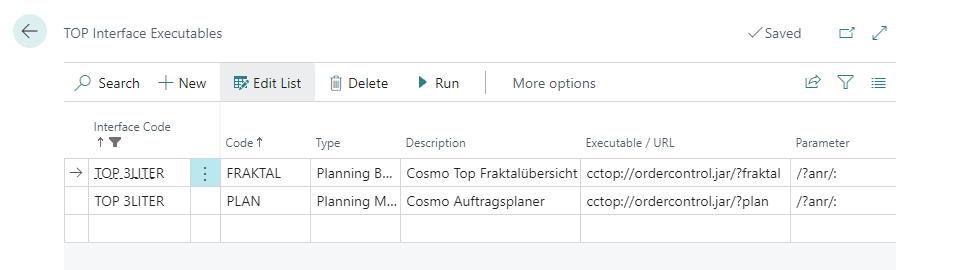

Executables Setup

It is possible to execute functionality of the external PPS directly from Microsoft Dynamics 365 Business Central (see Program Executables section). All possible interface executables can be configured in the TOP Setup (Interface menu).

The following table explains the fields of the TOP Interface Executables.

| Field | Description |

|---|---|

| Interface Code | Unique identifier (code) of the interface definition. |

| Code | Unique identifier of the interface definition (max. 20 characters). |

| Type | The type of module of the external PPS. |

| Description | Description of the program execution. |

| Executable / URL | Path/URL of the external program. |

| Parameter | Parameters which might be necessary for the program. |

| Default | Specifies the default program execution being used. This is preset when selecting a program call for execution. |

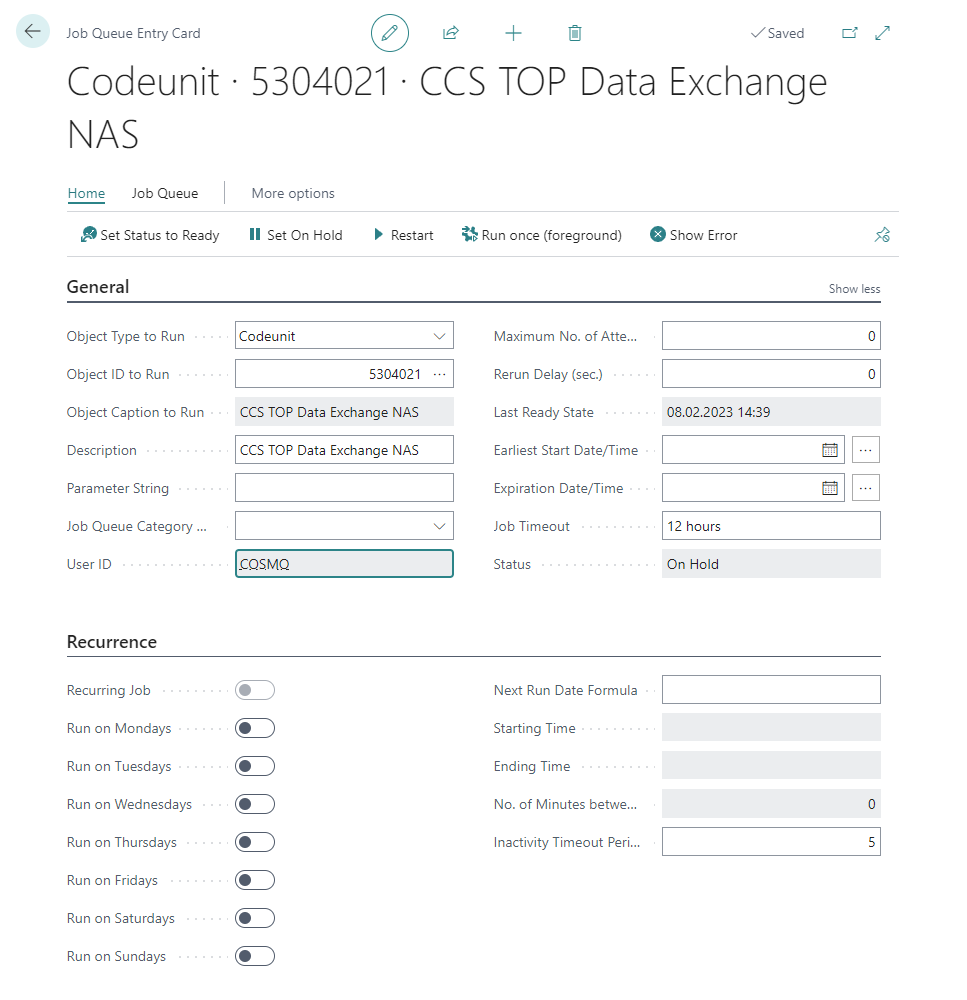

Automation Setup

To automate the interface, a corresponding entry must be set up in the Job Queue Entry.

Choose the  icon, enter Job Queue Entry, and then choose the related link. Select New to create a new entry.

icon, enter Job Queue Entry, and then choose the related link. Select New to create a new entry.

The following table explains the fields of the Job Queue Entry. Only the fields of the General FastTab that are relevant for setting up the automated execution for COSMO Task-Based Scheduling are explained. For the functionality of the remaining fields, see the Microsoft Job Queue Entries documentation.

| Field | Description |

|---|---|

| Object Type to Run | The CodeUnit option must be selected here. |

| Object ID to Run | The ID 5304021 ("CCS TOP Data Exchange NAS") must be entered here. |

| Parameter String | The value entered here can be used to specify which processing is to be automated by COSMO Task-Based Scheduling (several corresponding job queue entries can be used to control different processing in different ways). |

The following parameters are allowed for the parameter string:

- TRANSFER.OUTPUT – Transfer output (Microsoft Dynamics 365 Business Central to external PPS)

- TRANSFER.INVENTORY – Transfer inventory information (Microsoft Dynamics 365 Business Central to external PPS)

- TRANSFER.PURCHORDER – Transfer estimated purchase receiving (Microsoft Dynamics 365 Business Central to external PPS)

- TRANSFER – Transfers of Microsoft Dynamics 365 Business Central to external PPS with TRANSFER prefix

- PROCESS.PRODORDER – Import of planning data for production orders (external PPS to Microsoft Dynamics 365 Business Central)

- PROCESS.OUTPUT – Import of output (external PPS to Microsoft Dynamics 365 Business Central)

- PROCESS – All processing with PROCESS prefix

- [blank] – All data processing operations mentioned under TRANSFER and PROCESS

Feedback

Submit feedback for this page .