Data Transfer

The transfer of data between Microsoft Dynamics 365 Business Central and the external PPS is divided essentially into three scopes:

- Transfer of production orders to the external PPS including the complete production structure of Microsoft Dynamics 365 Business Central, as well as the retransfer of the planning results from the external PPS to Microsoft Dynamics 365 Business Central

- Transfer of output journal lines from Microsoft Dynamics 365 Business Central to the external PPS, as well as the transfer of output journal lines from the external PPS to Microsoft Dynamics 365 Business Central

- Transfer of data (inventory stock, purchase orders) for the material planning in the external PPS.

The following sections describe these three scopes in detail.

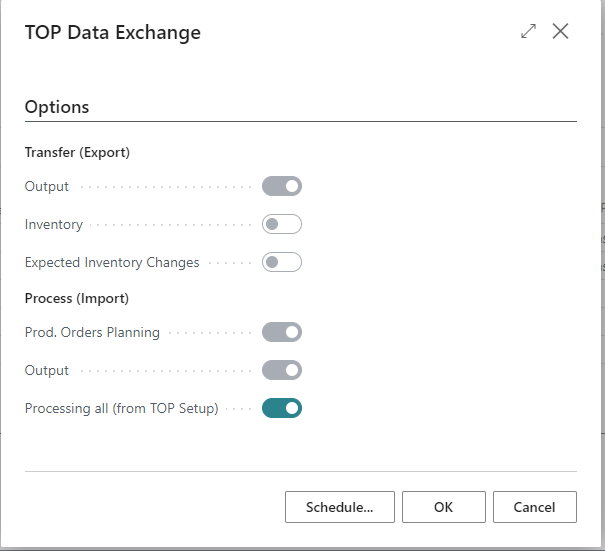

The data exchange can be automated (see Automation Setup) or can be accessed manually by choosing Manufacturing > Execution > TOP Reports and Analysis > TOP Data Exchange.

Production Orders

When you create a production order, the planning parameters (see Master Data Setup ) of the routing and BOM are copied to the routing and BOM of the production order. Here, the parameters can be set individually for this production order. The production orders are transferred to the external PPS with their entire production structure (BOMs, routings). Only rows that are provided with the corresponding planning relevance are transferred.

The transfer of production orders from Microsoft Dynamics 365 Business Central to the external PPS is usually done manually, i.e. the user decides which production orders should be planned in the external PPS, and transfers them with a simple push of a button. Similarly, after manual changes to a production order, it must be transferred again if these changes are relevant for planning.

The manual transfer can be done in two ways:

Single Prod. Order

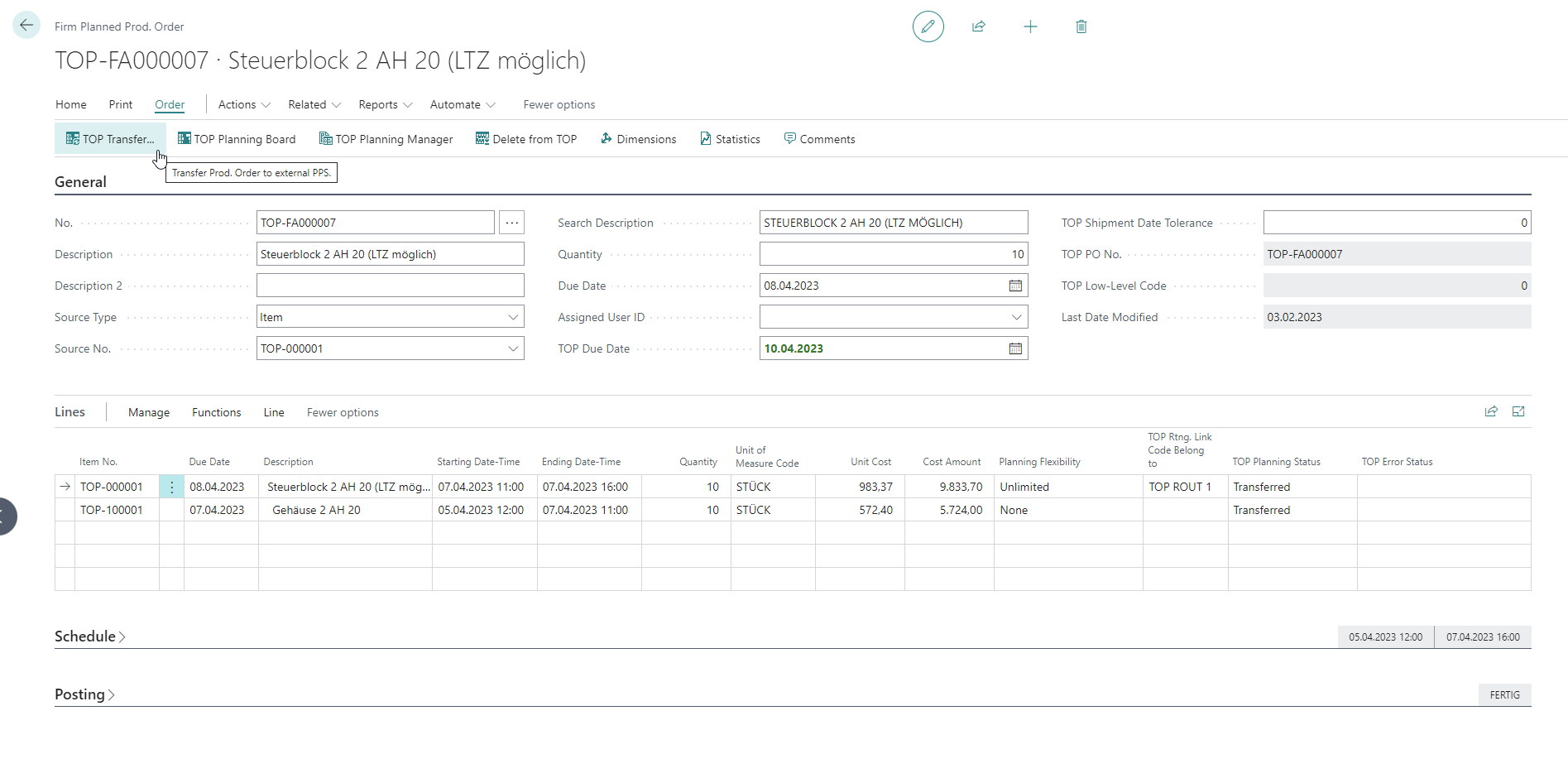

On the production order page, the TOP Transfer function is available in the Order menu.

Batch transfer // Todo

It is also possible to transfer any filtered production orders in one batch function by choosing the Manufacturing menu > Execution > TOP > Reports and Analysis > Transfer PO.

Furthermore, it is possible to automatically execute the transfer of a production order to the external PPS at certain program spots:

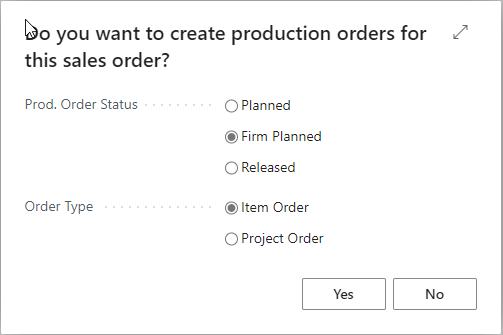

Create PO from a Sales line

When creating a production order from a sales line, it can be transferred automatically after the creation. The setting for this is in the TOP Setup.

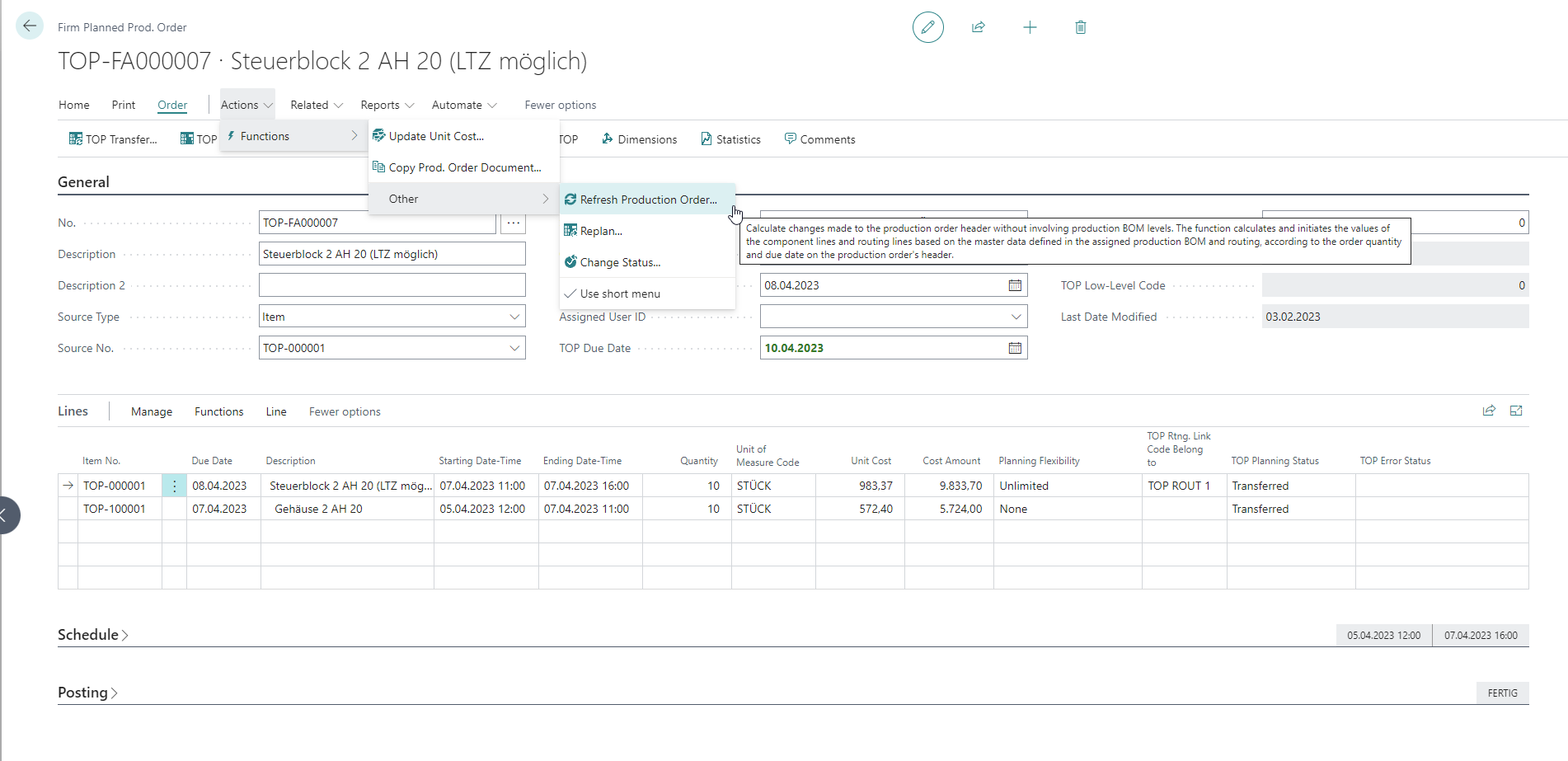

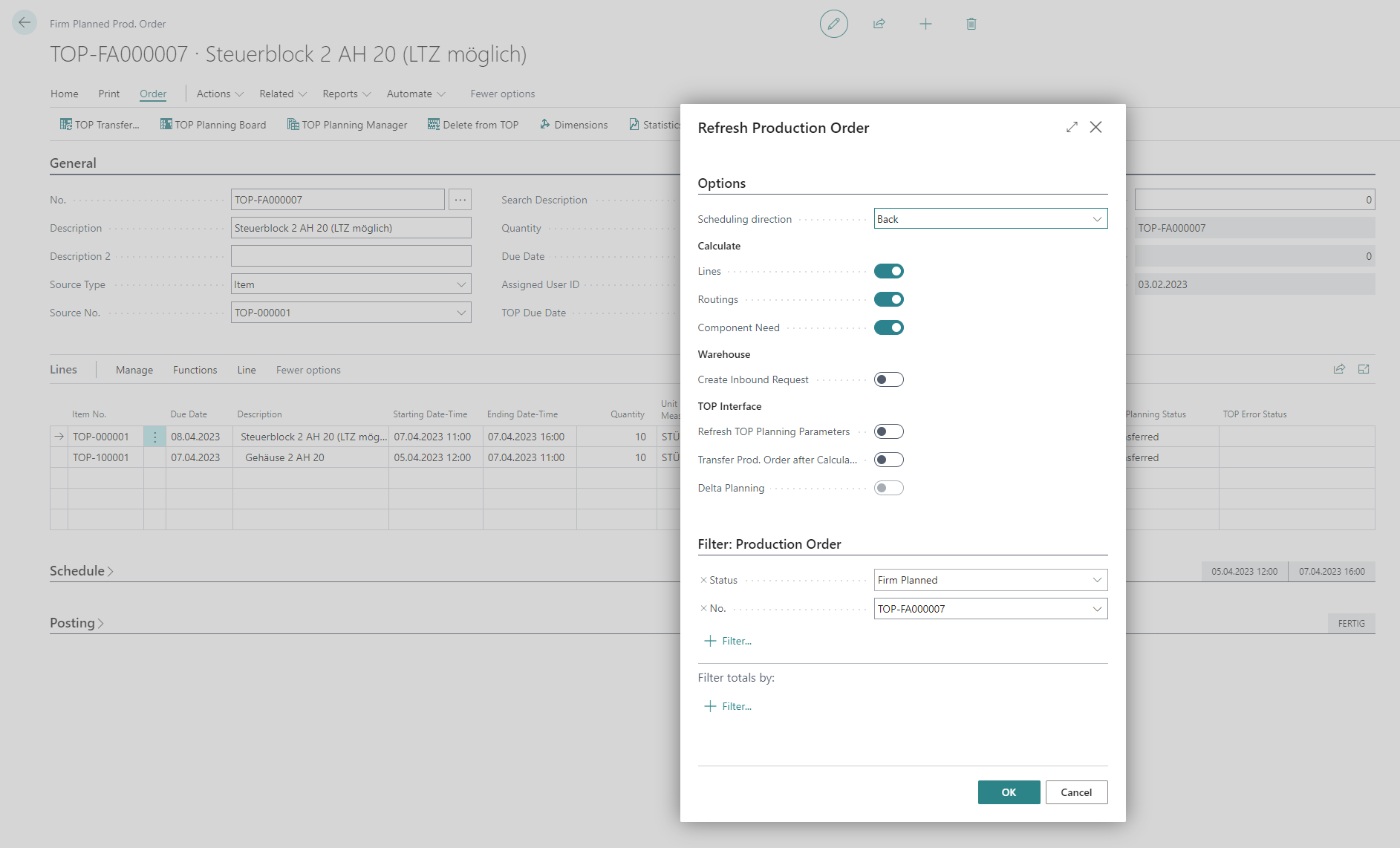

Refresh Production Order

If a production order is updated manually, it will also be transferred to the external PPS immediately after the calculation, depending on the setting in the TOP setup. For this purpose, there is a corresponding option in the report for refreshing the production order, which can already be preset by the corresponding setting in the TOP Setup. Furthermore, there is an option to refresh the TOP planning parameters while refreshing the production order. This means that the actual settings of the planning parameters from the corresponding work centers will be transferred to the respective routing lines.

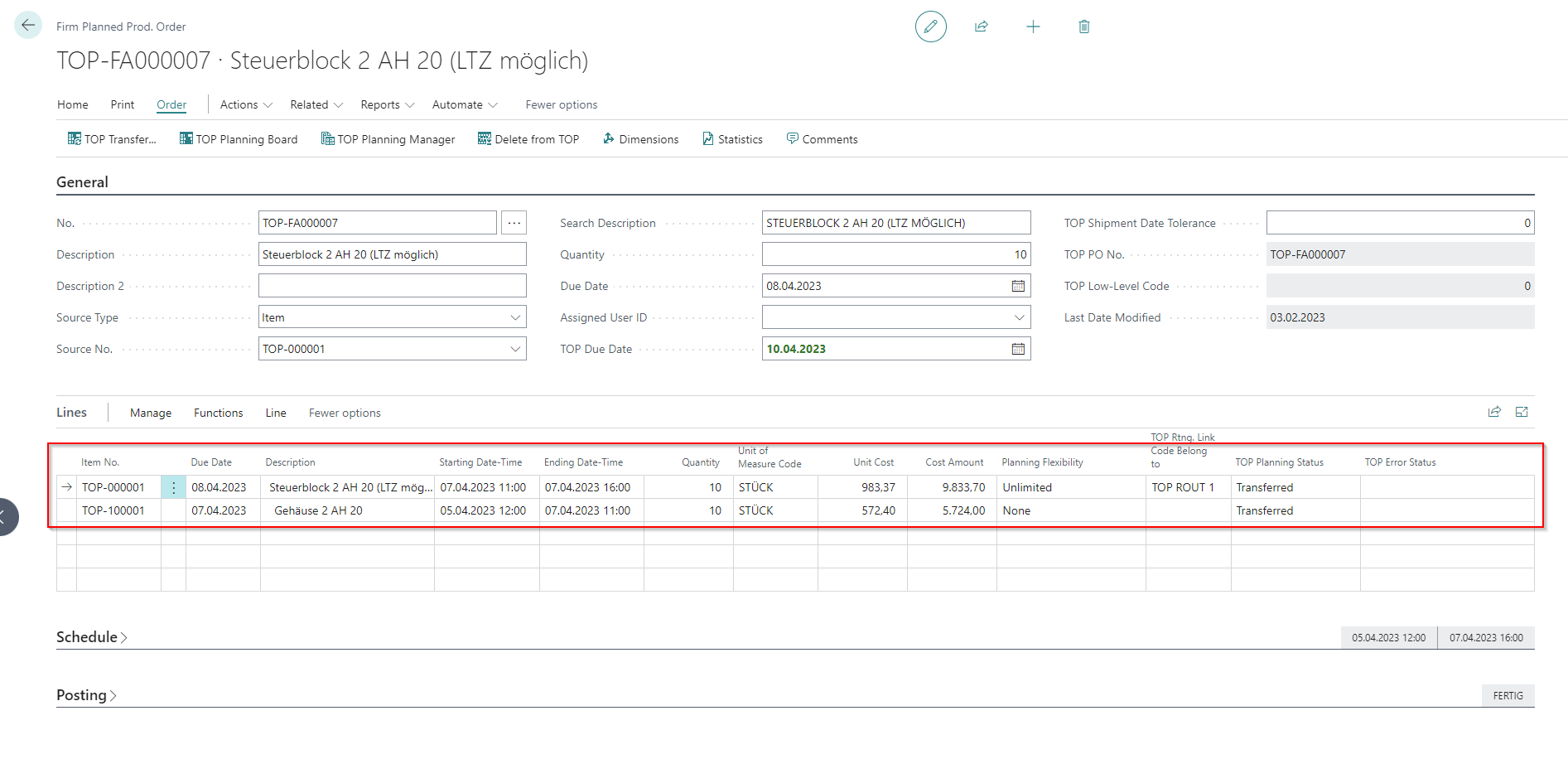

After planning a production order in the external PPS, the planning results are returned to Microsoft Dynamics 365 Business Central. The results are stored on the production order as follows:

At header level

- Due Date - Specifies the initial value on the basis of which the planning is carried out. However, after calculation of the planning in the PPS, it is modified depending on the result.

- TOP Due Date - Applies to planning only. Is assigned the initial value of the due date, but is not modified, so recalculations are always based on the initial due date. The color shows whether the due date has been exceeded (red) or not (green).

At the line level

- Start and End of each routing line based on the planning pot in which the routing line was scheduled.

- Start and End of each production order line based on start and ending time of the associated routing lines.

- Planning status of each production order. The following statuses are possible: o Unplanned – Production order has not been transferred to the external PPS yet o Transferred – Production order has been transferred to the external PPS o Red – Production order has been planned to status Red o Yellow – Production order has been planned to status Yellow o Green – Production order has been planned to status Green o Error – An error occured while planning. The error description can be found in the TOP Error Status field o Manually Planning – The production order could not be planned automatically, user interaction is necessary

Output Journal Lines

Output journal lines can be acquired in both systems (Microsoft Dynamics 365 Business Central and external PPS) and transferred from Microsoft Dynamics 365 Business Central to the external PPS as well as from the external PPS to Microsoft Dynamics 365 Business Central. The transfer from Microsoft Dynamics 365 Business Central to the external PPS is based on capacity ledger entries. Only output journal lines of production orders which were planned in the external PPS will be transferred. While transferring the output journal lines from the external PPS to Microsoft Dynamics 365 Business Central, output journal lines are created which have to be posted automatically or manually (see TOP Setup).

Inventory Stock & Expected Receipts

For material planning, it is also possible to transfer inventory stocks and expected receipts of open purchase orders from Microsoft Dynamics 365 Business Central to the external PPS. The transfer only takes place for items marked as Critical (according to item master). In this process, no changes are transferred, but always the current actual state of the system. This means, for all critical items the transfer-date-based available inventory stock, as well as the quantity to receive of the actual purchase orders together with their expected receipts, will be transmitted.

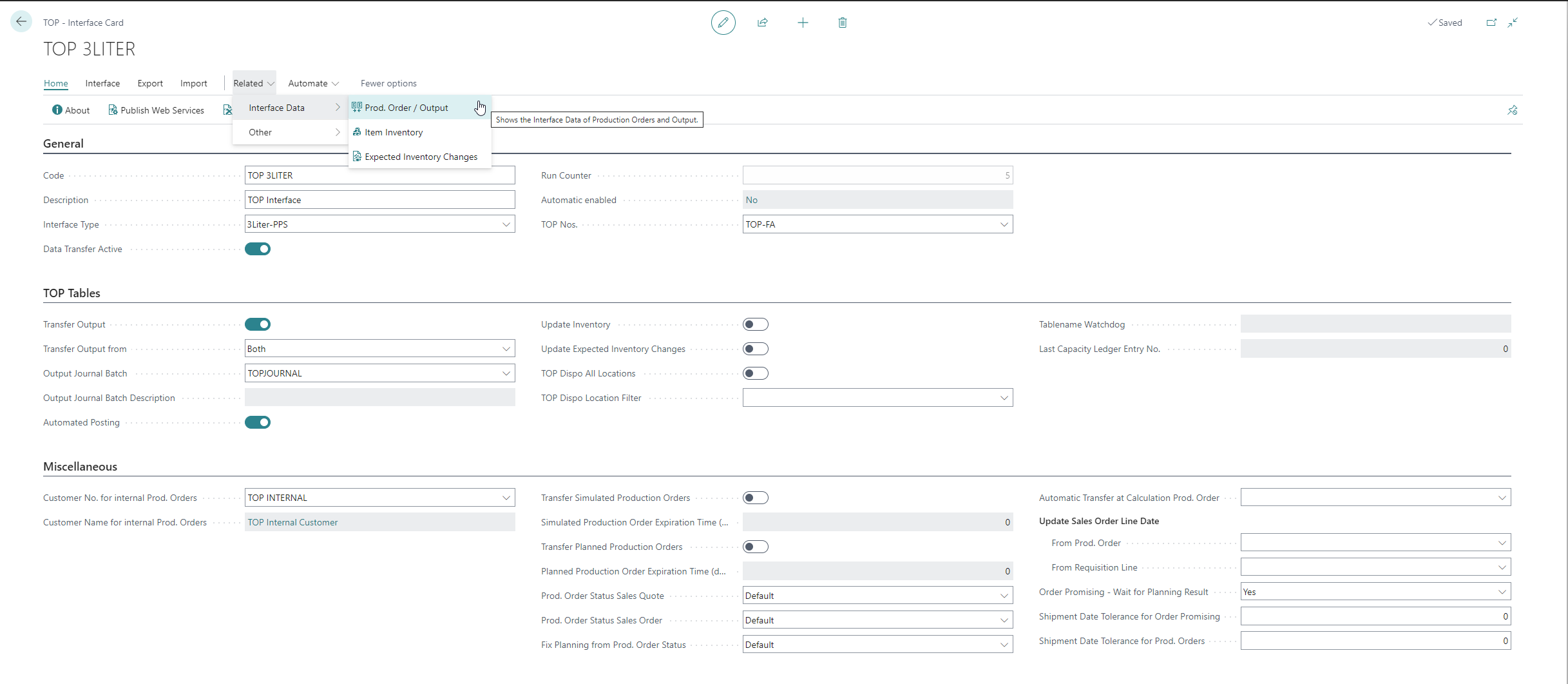

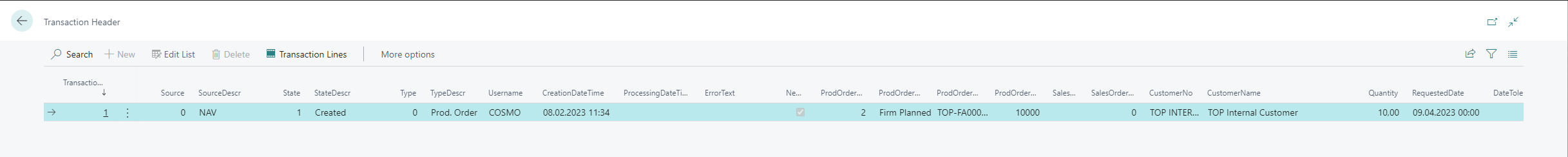

Prod. Order/Output

You can get an overview of the sent or received messages by choosing the Transactions view.

The fields to be displayed are described below:

| Field | Description |

|---|---|

| TransactionNo | Sequential Transaction Number |

| Source | System from which the message originates (0, 1) |

| SourceDescr | Name of the source system (Microsoft Dynamics 365 Business Central, PPS/3L) |

| State | Message status (0,1,2,3,4) |

| StateDescription | Description of the processing status (Created, Processed, Error, Error Handled) |

| Type | Message type (0,1,2,3,4) |

| TypeDescr | Description of the message type (Prod. Order, Correction, Finished, Output, Deltaplan) |

| Username | Originator of the message |

| CreationDateTime | Message creation date and time |

| ProcessingDateTime | Message processing date and time |

| ErrorText | Error text |

| NewPlanning | Specifies whether it is a new planning. |

| ProdOrderState | Production order status (0,1,2,3,4) |

| ProdOrderStateDescr | Production order status description (Simulated, Planned, Firm Planned, Released, Finished) |

| ProdOrderNo | Production order number |

| ProdOrderLineNo | Production order line number |

| SalesOrderNo | Sales order number |

| SalesOrderLineNo | Sales order line number |

| CustomerNo | Customer |

| CustomerName | Customer name |

| Quantity | Quantity in the prod. order |

| RequestedDate | Request date and time |

| DateTolerance | Specification (days) how large the deviation of the shipment date may be (see Shipment Date Tolerance) |

| Expiration | Time limit, after which the production orders are removed from planning in the PPS (see Expiration Time and [Order Promising](.. /special/functions-special-delivery-date-confirmation.md)) |

| CustomField1-10 | Customizable fields for transfer |

| 3L_State | Status in PPS/3L (0-6) |

| 3L_StateDescr | Status description of PPS/3L (Unplanned, Transferred, Red, Yellow, Green, Error, Manual Planning) |

| 3L_Errortext | PPS/3L error text |

| 3L_StartDateTime | PPS/3L Start date and time |

| 3L_EndDateTime | PPS/3L End date and time |

| 3L_DeliveryDate | Shipment date and time of the PPS/3L |

Feedback

Submit feedback for this page .