Master Data Setup

For the use of COSMO Task-Based Scheduling, some enhancements have been made to the master data for manufacturing. This is described in this section.

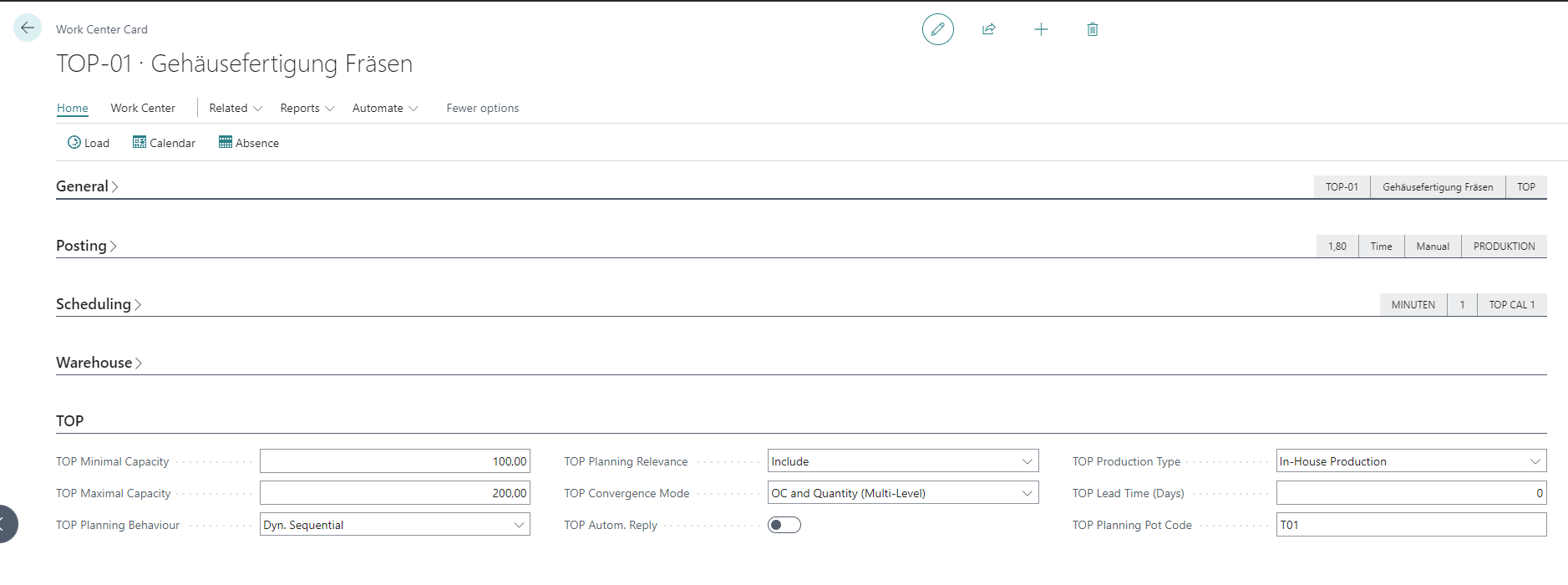

Work Center Card

The work centers in Microsoft Dynamics 365 Business Central correspond to the planning pot-rows (= departments / resource groups) with their stored disposition of the time grid (= planning pots) in the external PPS, in which the routings of the production orders to be planned are scheduled.

For the control of the planning in the external PPS, additional information can / must be set on the work centers. Those will be inherited to their related routing lines and are used as a guideline for the creation of new routing lines. Therefore, a new FastTab with additional information has been created on the work center card.

TOP FastTab

| Field | FastTab | Description |

|---|---|---|

| TOP Minimal Capacity | TOP | Specifies the minimum capacity for scheduling a routing line in this planning pot. Check the documentation of the external PPS for a more detailed description of this planning parameter. |

| TOP Maximal Capacity | TOP | Specifies the maximum capacity for scheduling a routing line in this planning pot. Check the documentation of the external PPS for a more detailed description of this planning parameter. |

| TOP Planning Behaviour | TOP | Default behaviour for scheduling a routing line in this planning pot (Standard, Sequential, Sequential Linked 1, Sequential Linked 2, Sequential Linked 3, Dyn. Sequential, Dyn. Sequential Linked 1, Dyn. Sequential Linked 2, Dyn. Sequential Linked 3). Check the documentation of the external PPS for a more detailed description of this planning parameter. |

| TOP Planning Relevance | TOP | Default for the relevance of scheduling a routing line in this planning pot. The options are: Ignore (The routing line will be transferred to the external PPS, but not considered capacitively for the planning), Include (The routing line will be planned capacitively), No Transfer (The routing line will not be transferred to the external PPS). Check the documentation of the external PPS for a more detailed description of this planning parameter. |

| TOP Convergence Mode | TOP | Default for the convergence of scheduling a routing line in this planning pot. The options are: No Convergence, OC only (Single-Level), OC and Quantity (Single-Level), OC only (Multi-Level), OC and Quantity (Multi-Level). For a detailed description of this planning parameter, please refer to the documentation for the external PPS. |

| TOP Autom. Reply | TOP | Specifies if routing lines automatically generate a response. Check the documentation of the external PPS for a more detailed description of this planning parameter. |

| TOP Production Type | TOP | Default for the production type of a routing line in this planning pot. The options are: In-House Production, External Production, Construction. Check the documentation of the external PPS for a more detailed description of this planning parameter. |

| TOP Lead Time (Days) | TOP Tables | Specifies the delivery time of routing lines which are manufactured external (TOP Production Type = External Production). Check the documentation of the external PPS for a more detailed description of this planning parameter. |

| TOP Planning Pot Code | TOP Tables | Unique identifier of the related planning pot in the external PPS. |

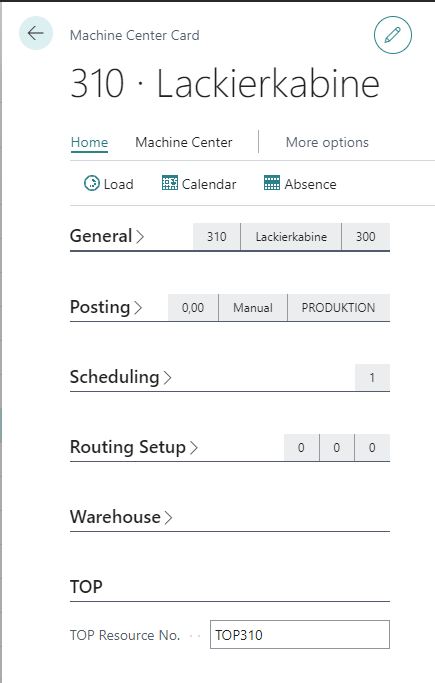

Machine Center Card

The machine centers have been extended to include the TOP FastTab with the TOP Resource No. field for data exchange with the external PPS. This is the unique identifier of the related resource in the external PPS.

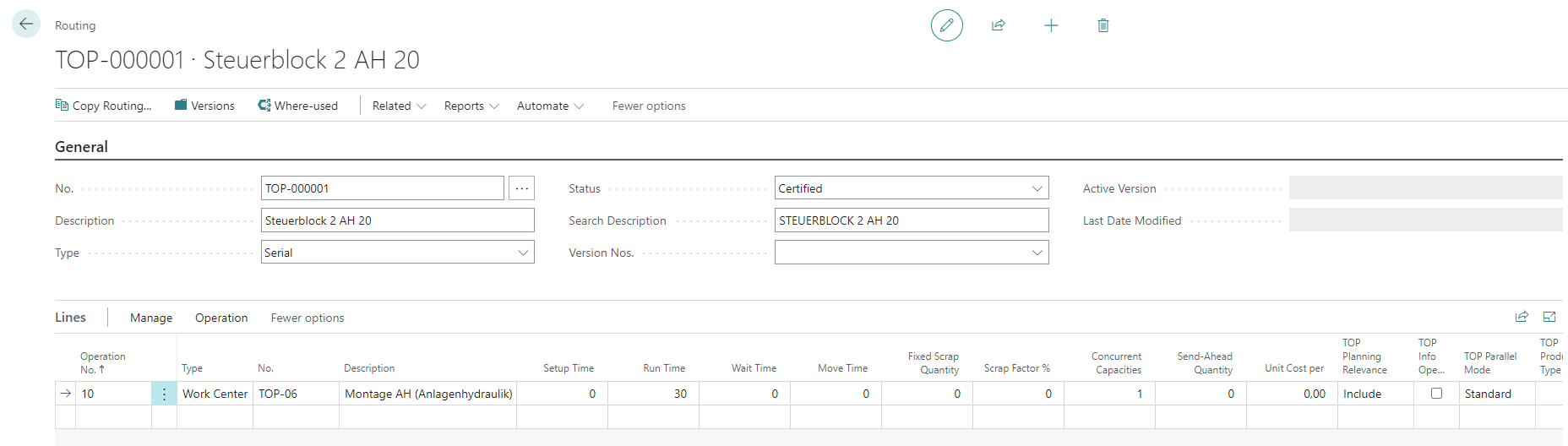

Routing

While assigning a machine center / work center to a routing line, the TOP planning parameters of the related work centers will be copied to the routing line and can be re-adjusted individually for this routing line over here. The routing lines have been extended with the following fields.

The following table explains the extended fields of the routing line. For the description of the planning parameters identical to the work center, see the work centers section. Only additional fields are explained here.

Routing - Lines

| Field | FastTab | Description |

|---|---|---|

| TOP Info Operation | TOP | Select this field if you want the routing line to go for informational purpose only and not being scheduled capacitively in the corresponding planning pot. Check the documentation of the external PPS for a more detailed description of this planning parameter. |

| TOP Parallel Mode | TOP | Controls the parallel processing of routing lines. The options are: Standard, Simultaneous to Next Operation, Synchronous to Next Operation. Check the documentation of the external PPS for a more detailed description of this planning parameter. |

| TOP Dispo | TOP Tables | Specifies the vendor for routing lines that are manufactured externally (TOP Production Type = External Production). Check the documentation of the external PPS for a more detailed description of this planning parameter. |

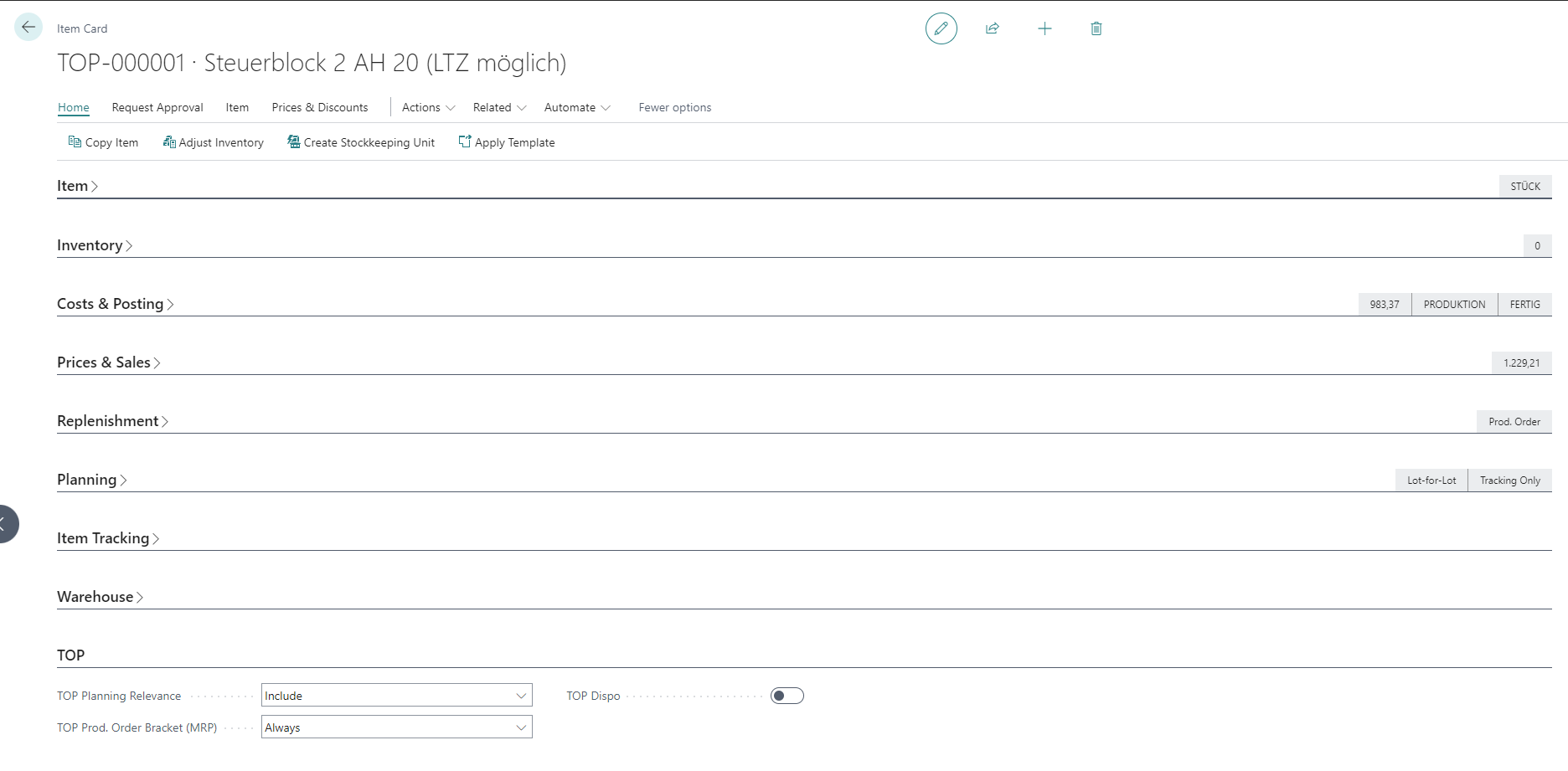

Item Card

| Field | FastTab | Description |

|---|---|---|

| TOP Planning Relevance | TOP | Planning relevance of the item in the external PPS. Check the documentation of the external PPS for a more detailed description of this planning parameter. |

| TOP Prod. Order Bracket (MRP) | TOP | Controls the creation of the order bracket for the item, when using the item as an assembly (see Order Bracket). |

| TOP Vendor No. | TOP | Use the dispo module of the external PPS for the item. |

Bill of Materials

COSMO Task-Based Scheduling is primarily used for capacity-checked planning of production orders. However, it is also possible to check the availability of required materials and to schedule them, if necessary. In general, availability is only checked for materials (items) that are marked TOP Planning Relevance "Include" or similar in the item master. In addition, further settings can be made on the BOM components for control in the external PPS.

Additional Fields

TOP Planning Relevance

Controls the relevance of the component in terms of material requirements (prerequisite is the identification of the respective item as Critical). The following options are possible:

- Ignore - The material requirements are ignored (the component will not be transferred to the external PPS)

- Include - The material requirements of the component are considered

- Include and Initialize – The material requirements of the component are considered and an additional operation for the material's deployment is being generated in the external PPS

- Include and Order – The material requirements of the component are considered and an additional operation for the stock receipt considering the lead time is being created in the external PPS

- Include & Initialize and Order– The material requirements of the component are considered and an additional operation for each the stock receipt and material's deployment is being created in the external PPS

Check the documentation of the external PPS for a more detailed description of this planning parameter.

TOP Dispo

Select if you want to check the availability of the material (considering the inventory stock, expected receipts and lead time). Check the documentation of the external PPS for a more detailed description of this planning parameter.

Feedback

Submit feedback for this page .