Plant Maintenance

Plant Maintenance in COSMO Process Manufacturing provides basic functions, such as a maintenance plan and the implementation and consumption of material and staff to make reservations.

Generally, it is important that the time frame for the machine maintenance is adjusted with the production planning of the same machine.

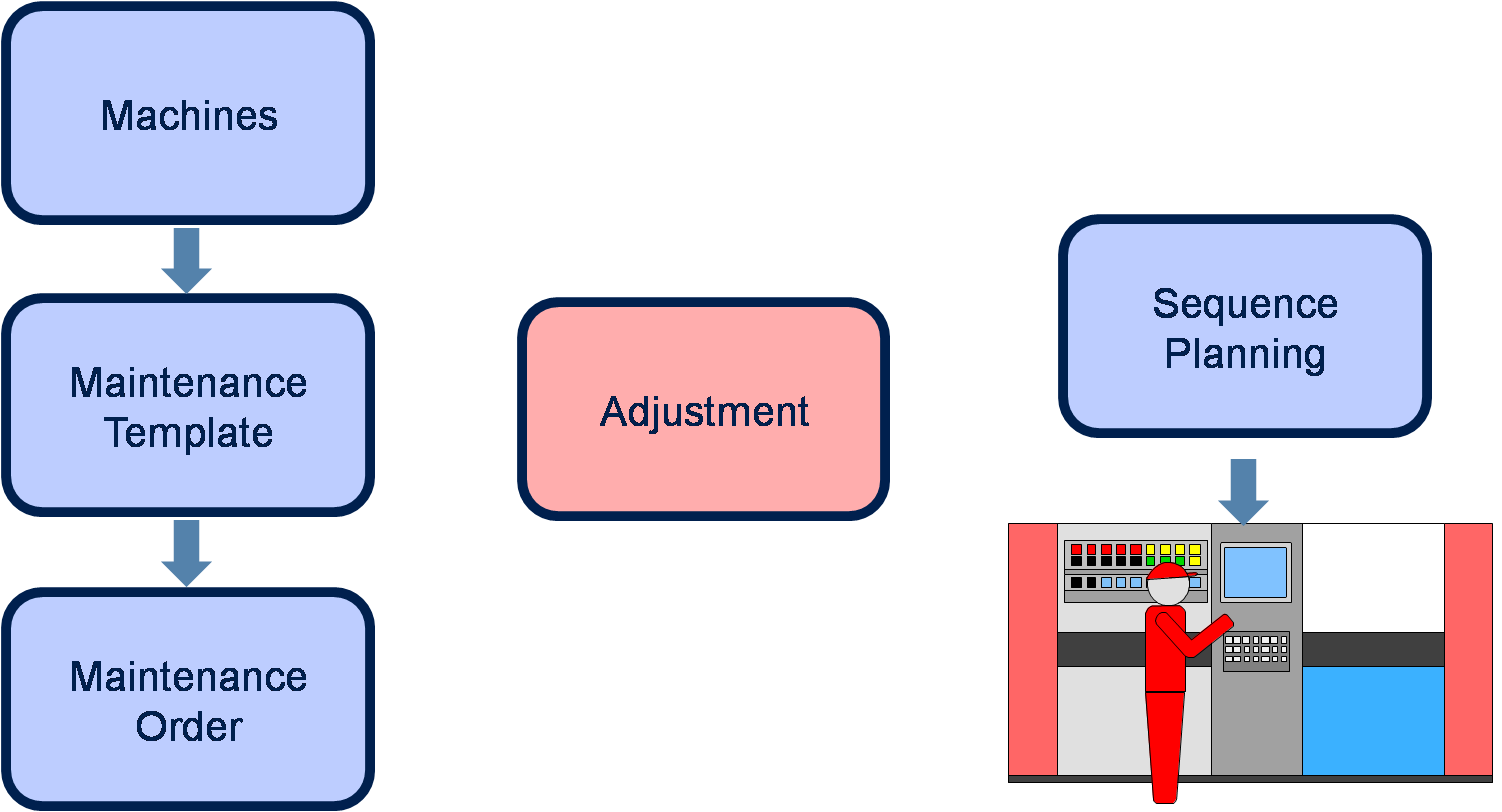

The main goal of the Plant Maintenance functionality is to provide a connection between the maintenance orders from plant maintenance and the maintenance/setup orders from process manufacturing. This functionality also allows you to adjust these orders as needed. A visualized scheduling tool provides an overview of maintenance orders as well as assists in scheduling or rescheduling orders.

The figure above illustrates the process for maintenance (machinery, maintenance contract templates, maintenance order), and coordination with the production, on the same machine where multiple production orders are scheduled.

The following table describes a sequence of tasks, with links to the topics that describe them.

| To | See |

|---|---|

| Define settings for plant maintenance. | Setup |

| Learn how to create standard maintenance orders with or without a template. | Standard Maintenance Orders |

| Learn how to process periodic and usage-based maintenance. | Periodic and Usage-Based Maintenance |

| Learn how to create breakdown maintenance orders. | Breakdown Maintenance Orders |

| Confirm and post standard and breakdown maintenance orders. | Confirmation and Posting |

| View and schedule standard maintenance orders using a visualized scheduling tool. | Graphical Maintenance Scheduling |

Feedback

Submit feedback for this page .