Demo Application

- What is the demo application and what is its purpose?

- How can it be accessed and used?

- In which languages is it available?

- What types of processes can be demonstrated using the demo application?

Tip

Summary: This guide provides instructions on how to use the demo application of COSMO Mobile Solution. It includes details on supported languages, available processes, and useful tips for utilizing the solution effectively.

The demo application is designed to provide a hands-on experience and a visual representation of COSMO Mobile Solution. It allows users to explore the application's functionalities via simple processes.

Important

The application backend is not accessible to users, meaning configuration modifications are not possible. The configuration, test data, and processes are predefined by the product development team. Note that the backend environment is reset daily at 12:00 p.m. (GMT+1). As the environment is publicly available, data inconsistencies may occur, so seamless execution of all processes cannot be guaranteed due to parallel access.

Access the Demo Application

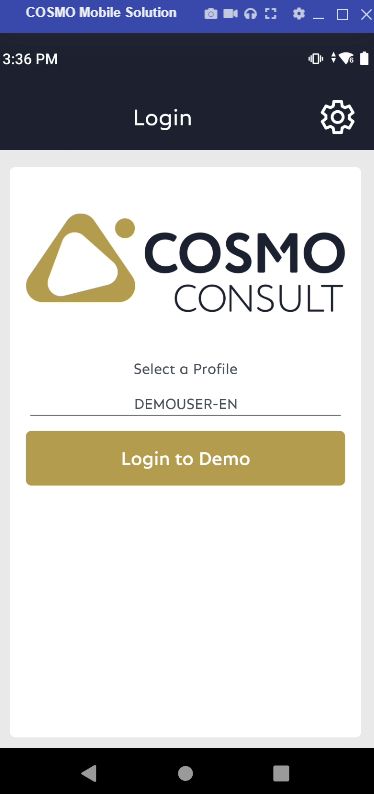

Upon installing the mobile application on an Android device, launching COSMO Mobile Solution will display the initial login screen.

[WARNING!] The use of any kind of Android emulators is not supported due to unstable functionality.

To access the Demo Environment, select a user and press the Login to Demo button. No password or PIN code should be needed.

If the application was previously connected to a real environment, clearing the intermediate layer will restore the initial screen with demo login credentials.

Available Users and Languages

The application language is determined by the selected user. The following user accounts and languages are available in the demo application:

- DEMOUSER-DE: German

- DEMOUSER-EN: English

- DEMOUSER-ES: Spanish

- DEMOUSER-FR: French

- DEMOUSER-HU: Hungarian

- DEMOUSER-SV: Swedish

Available Processes

The demo application does not include the complete base configuration of COSMO Mobile Solution. Instead, it offers a limited, compact configuration package that enables the testing of simplified processes.

Data

Locations

WHSEPROC: Warehouse processes (Warehouse Receipt, Warehouse Put-away, Warehouse Shipment, Warehouse Pick)

- Bin mandatory

- Receipt mandatory

- Put-away mandatory

- Shipment mandatory

- Pick mandatory

- Bins created

- Receipt and Shipment bins

- Bin for the Movement process for COSMO Mobile Solution

- Manufacturing bins (To-production and From-production)

INVPUTPICK: Inventory processes (Inventory Put-away, Inventory Pick)

- Bin mandatory

- Put-away mandatory

- Pick mandatory

- Bins created

- Bin for the Movement process for COSMO Mobile Solution

- Manufacturing bins (To-production and From-production)

Items

- Finished Item: Wine Cooler - 70065

- BOM assigned

- Routing assigned

- Lot Material: Metal Sheet 1 x 1 m - 70064

- Serial Material: Compressor - 70063

- Not-tracked Material: Screw - 70062

- Not-tracked Material: Shelf - 70061

- Bicycle - 1000

- Finished Item: Wine Cooler - 70065

Inventory

WHSEPROC Location:

- A1: 70061 - 200 pcs

- A2: 70062 - 1000 pcs

- A3: 70063 - 60 pcs (Ser)

- A4: 70064 - 500 pcs (10 lots)

- FINISHED: 70065 - 5 pcs

- A3: 1000 - 20 pcs

INVPUTPICK Location:

- B1: 70061 - 200 pcs

- B2: 70062 - 1000 pcs

- B3: 70063 - 60 pcs (Ser)

- B4: 70064 - 500 pcs (10 lots)

- FINISHED: 70065 - 5 pcs

- B3: 1000 - 20 pcs

Processes

There are seven roles in the demo application.

Receipt

- Warehouse Receipts

- Warehouse Put-away Lines

- Inventory Put-away Lines

Shipment

- Warehouse Shipments

- Warehouse Pick Lines

- Inventory Pick Lines

Movement

- Movement: Barcode scanner optimized process of COSMO Mobile Solution (background: Item Reclass. Journal posting)

- Find Items: Real-time inventory report of COSMO Mobile Solution with a filter and a result page

Manufacturing

- Released Production Orders

- Consumption Calculation and Posting (available on Prod Order Headers and Prod. Order Lines)

- Output Calculation and Posting (available on Prod Order Headers and Prod. Order Lines)

- BOMs

- Routings

Physical Inventory

- Barcode scanner optimized process of COSMO Mobile Solution (background: Inventory Recordings)

Inventory Adjustment

- Barcode scanner optimized process of COSMO Mobile Solution (background: Item Journal posting)

Data

- Items

- Locations

- Posted and registered documents

Items with mandatory tracking are color-coded for each process. Serial tracked items are indicated in orange, lot tracked items are indicated in light blue, and non-tracked items have no color.

Receipt:

WHSEPROC Location:

- Three Purchase Orders (106025, 106026 and 106027) - two from the same vendor, one from a different

- One Warehouse Receipt (RE000005) for one Purchase Order (106027), can be posted, Warehouse Put-away Lines will be created automatically (item tracking should be provided)

- One Warehouse Receipt (RE000007) for one Purchase Order (106029), can be posted, Warehouse Put-away Lines will be created automatically

- One Warehouse Receipt (RE000008) for two Purchase Orders (106034 and 106035), can be posted, Warehouse Put-away Lines will be created automatically

- One empty Warehouse Receipt Header (RE000011), lines should be created with Get Source Doc., source Purchase Order No.: 106036

- One Purchase Order for Bicycle parts (106028), Warehouse Receipt can be created manually by choosing the New button on the Warehouse Receipt List and using the Get Source Doc. function (the Location Code should be provided)

- One Posted Whse. Receipt with non-posted Put-aways (for Purchase Order 106028): PU000003

INVPUTPICK Location:

- Four Purchase Orders (106030, 106031, 106032, 106033)

- Inventory Put-away Lines are created (IPU000001, IPU000002 - item tracking should be provided, IPU000003, IPU000004)

Shipment:

WHSEPROC Location:

- Four Sales Orders (1001, 1002, 1003, 1004) - some from the same customer, others from a different one

- One Warehouse Shipment (SH000005) for one Sales Order (1001), Warehouse Pick Lines can be created with the Create Pick function (per line or on the header), the Pick can be registered, and the Shipment can be posted

- One Warehouse Shipment (SH000006) for two Sales Orders (1002 and 1003), Warehouse Pick Lines are created (PI000003), they can be registered (item tracking should be provided for one of the lines), the Shipment can be posted

- One Warehouse Shipment (SH000007) for one Sales Order (1004), Warehouse Pick Lines can be created with the Create Pick function (per line or on the header), the Pick can be registered, and the Shipment can be posted

- One Sales Order (1007) for a tracked item and a non-tracked item, Warehouse Shipment can be created manually by choosing the New button on the Warehouse Shipment List and using the Get Source Doc. function (the Location code should be provided), item tracking should be provided

INVPUTPICK Location:

- Two Sales Orders (1005, 1006)

- Inventory Pick Lines are created (IPI000001 - item tracking should be provided, IPI000002)

Movement:

- Find items: Inventory can be checked via the Find Items functionality by providing the necessary filters

- Movement: By providing the Source Location Code and the Source Target Bin, it's possible to scan several lots/serial numbers and moving them to a different bin or/and location after providing the Target Location Code and Target Bin Code (the required settings are already made, like Movement Bins and the Item Reclass. Journal templates and batches for the specific user)

Manufacturing:

- WHSEPROC Location, To-production bin: RAWMAT, From-production bin: FINISHED

- Manufactured items: 1000, 70065

- Components for 1000: 1100, 1200, 1300, 1400, 1450, 1500, 1600, 1700, 1800, 1850, 1900

- Components for 70065: 70061, 70062, 70063, 70064

- Released Prod. Orders: 10104, 10105, 1011002, 1011003, 101104 (1011002 and 1011003 have posted Consumption and Output on them)

- Consumption and Output can be calculated via the functions on Prod. Order Headers or Prod. Order Lines (Calc. Cons. and Calc. Output buttons)

- Consumption and Output can be posted via the functions on Prod. Order Headers or Prod. Order Lines (Cons. and Output buttons)

- BOMs

- Routings

Physical Inventory:

- One Physical Inventory Recording for WHSEPROC Location (PHI000002)

- One Physical Inventory Recording for B Location (PHI000003)

- Calculated lines for both Recordings (can be accessed by using the Rec. Lines List function on the Phys. Inv. Recording Header)

- Blind recording is also possible for both Recordings (can be accessed by using the Add Rec. Lines function on the Phys. Inv. Recording Header)

Inventory Adjustment:

- Positive and Negative Adjustment can also be posted

- The required settings are already made, like Item Journal templates and batches for the specific user

Feedback

Submit feedback for this page .