Usage

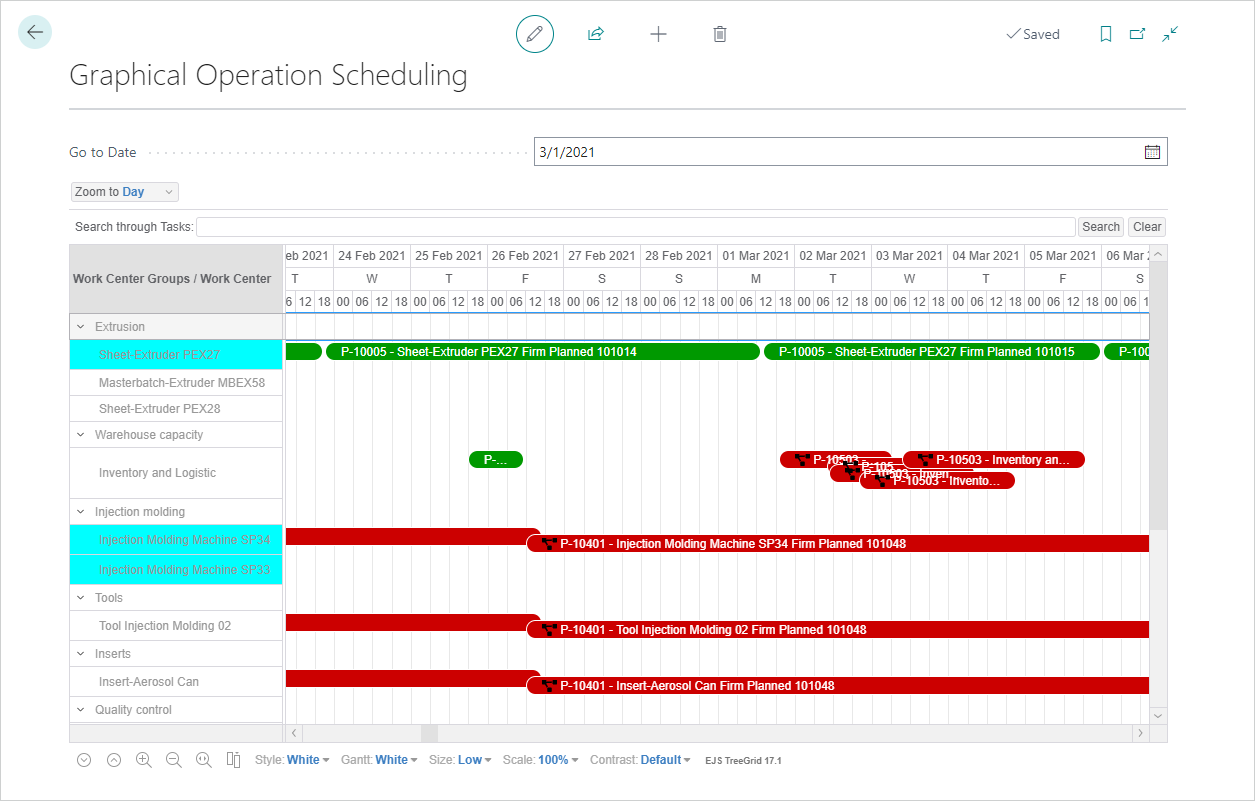

The purpose of the Graphical Operation Scheduling page is to provide an overview of all operations for any type of work center (sequence, non-sequence (standard BC), tools, and inserts) as well as the scheduling of their related production orders visualized in a single line. The view is limited to operations and shows no capacity load, but it is possible to navigate to the related Work Center Load page via context menus.

Work Centers

The left pane shows the work center groups and related work centers. Work centers that need to be rescheduled are highlighted in aqua by default (this color can be changed in the Graphical Extension Setup page).

Tap (or hover the cursor over) over the entries to see the numbers/names of the work center/work center group and whether scheduling is required, tap and hold (or right-click) to open the context menus.

Production Orders

The right pane of the chart shows production orders related to the work centers, displayed on a single line based on the time frame. You can use colors to differentiate between standard production orders and those with special indicators (Standard Color and Notification Color in Graphical Extension Setup page).

Tap (or hover the cursor over) the production order information to see the production order information including number, Start/End Times, and Due Date of the production order; tap and hold (or right-click) to open the context menus.

The production orders also include special icons to indicate material shortages, capacity conflicts, and resource needs. These icons are shown before the item number.

Production Order Adjustments

You can move production orders either within the same work center or to a new work center directly in the Graphical Operation Scheduling page to resolve conflicts or to manage materials and resources using the standard drag-and-drop or the Change Work Center action.

Note

In some cases, a message may open stating "There is no allocation for the work center [number] and the tools/inserts in the routing. The tools/inserts will be deleted. Do you want to continue?". If you do not want to delete the tools/inserts, then choose the No button.

Drag-and-Drop

You can use the standard drag-and-drop function to move an operation backward and forward in time, but it also possible to move it from one work center to another. The production rate will be considered for calculating the time needed to perform the operation on the target work center.

While moving production orders, a tooltip shows the new dates and times of the potential change.

No message opens to confirm the move and the change is made immediately. The work center is not set for recalculation.

Using this method, the tool/insert remains untouched and the production operation uses the latest production rate.

Change Work Center

You can use the Change Work Center action to move an operation from one work center to another, which will adjust the sequence planning accordingly because of the synchronization between production operation and tool/insert operation.

From the context menu, choose the Change Work Center action to open the Work Centers page where you can choose the new work center. A message opens asking to confirm the move. Adjusted production orders appear as grey while processing the changes. Once the changes are processed, the production orders return to their original color. The work center color will change to the specified color because it needs to be rescheduled.

This option supports tools and inserts better than using drag-and-drop because the production rates will be updated next to the sequence work center operation as well as to the tool/insert operation.

See Also

Feedback

Submit feedback for this page .