Production Structure Setup

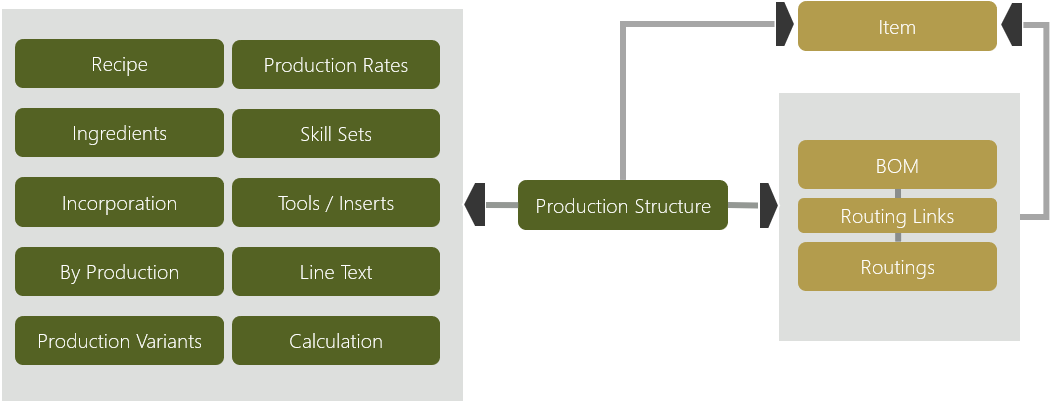

The Production Structure is used to manage recipes, routings, BOMs, and comments in one page. A Production Structure can be set up for one item but used for other items as well.

In the Production Structure page, new production structures can be created and existing ones can be edited.

General FastTab

The fields on this FastTab are described in the following table.

| Field | Description |

|---|---|

| No. | Unique identifier for the production structure. |

| Production Structure Type | Identifies the type of the production structure. The options are: - <Blank>: No type is assigned. - Development Structure: In the production structure header, the Item No. field but be empty. In the production structure lines, with Type = Item or Share of Recipe, the No. field must be empty. - Laboratory Structure: In the production structure header, the Item No. field but be empty. In the production structure lines, with Type = Item or Share of Recipe, the No. field must be filled in. - Manufacturing Structure: In the production structure header, the Item No. field must be filled in. In the production structure lines, with Type = Item or Share of Recipe, the No. field must be filled in. - Bottling Structure: Used to bottle items in different units of measure (see Bottling Production Structure). |

| Sample Shipment | Determines if a sample shipment is made for the production structure and if so, the Sample Shipment page is accessible to enter more information to the sample shipment. |

| Item No. | Number of the item the production structure is for. When the production structure is certified, the new Routing and Production BOM will be linked to this item. |

| Description / Description 2 | Descriptions from the Item Card. |

| Unit of Measure Code | Determines the values of the corresponding production structure lines. The Unit of Measure Code is transferred to the production BOM, if used. If this field is changed in an existing Production Structure, the quantity and times in the Production Structure lines are automatically updated. |

| Lot Size | Identifies the lot size of the production structure. The lot size is used if a production order is created from the production structure or if it is used to make a production structure simulation. When the production structure is certified, the value in this field will be copied to the Lot Size field on the Item Card. |

| Status | Indicates which processing status a production structure has. The options are: - New: The production structure is new. - Certified: The production structure is certified and ready for use. - Under Development: The production structure is in progress. - Closed: The production structure has been closed. |

| New Production BOM | Determines if – during the certification of a production structure – the existing production BOM should be revised or if a new production BOM version should be created. |

| New Routing | Determines if – during the certification of a production structure – the existing routing should be revised or if a new routing version should be created. |

| Creation Date | Date the production structure was created. |

| Last Date Modified | Date the production structure was last modified. |

| Production BOM No. | Number of the valid production BOM. - If it is a standard BOM, this field contains the manufacturing BOM number. - If it is a recipe BOM, this field contains the recipe BOM number. |

| Production BOM Version Code | BOM version code of the production BOM. - If it is a standard BOM, this field contains the manufacturing BOM version code. - If it is a recipe BOM, this field contains the recipe BOM version code. |

| Routing No. | Number of the valid routing. |

| Routing Version Code | Number of the routing version code. |

| Recipe Comparison Group Code | Specifies a filter for comparison and assigns a structure to a group that matches the filter. It determines which Production BOMs/Production BOM Versions will be used for comparison in the Matrix FastTab of the Recipe Comparison Matrix page (see Recipe Comparison Matrix, Filter FastTab). |

| Max. Incorporation % | Defines a limited quantity of incorporation item in this recipe that is created from a production structure. This field contains the maximum percent share of incorporation item relating to the entire recipe. |

Lines FastTab

The production structure lines are used to register the component and routing positions. The Type field determines the type of information in the line. Depending on the type, different information is necessary.

The fields on this FastTab are described in the following table.

| Field | Description |

|---|---|

| Type | Determines the type of information in the Production Structure line. The options are Work Center, Machine Center, Item, Share of Recipe, Production BOM, Tool, Standard Task Personnel, Standard Task Quality Measure, Standard Task Tool, Main Recipe, and Insert. NOTE: Both Inventory and Non-Inventory item types can be used in the production structure line with Type = Item or Share of Recipe. |

| No. | Identifies the number of the related item, work center, machine center, production BOM/recipe, or standard task. |

| Description | Displays the description of the related Type / No. combination or user-defined description for types without numbers. |

| Quality per | Calculates the quantity of the component consumed to manufacture the output item. If a Calculation Formula is not specified, then the Quantity Per defines how many units of the component are consumed to manufacture one unit of the output item. Used with Type = Item and Production BOM. |

| Share % | Indicates a ratio expressed as a fraction of 100% of one unit of the output item. It is used to calculate quantity to be consumed of the component. Used with Type = Share of Recipe. |

| Shares | Indicates the share of an item or substance. Within a production structure the sum of all shares and share % must be 100%. For example, if in some item lines the Share is filled out, Share % will be calculated when the production structure will be certified. Used with Type = Share of Recipe. |

| Setup Time | Indicates the time a machine or work center needs to convert from the production of the last piece of item A to the first piece of item B. Used with Type = Work Center and Machine Center. |

| Run Time | Indicates the time a machine or work center needs to run a process. The run time is handled per lot size of the produced item and does not include the setup time. Used with Type = Work Center and Machine Center. |

| Res. Planning Group Code | Indicates the resource planning group that classifies the resources used in the Resource Shift Schedule Overview page. Used with Type = Work Center and Machine Center. For more information, Resource Planning Groups. |

| Calculation Group Code | Indicates the code that groups work centers, machine centers, and items for calculation purposes (see Calculations for Production Structures). |

| Unit of Measure Code | Indicates the unit of measure of Type = Item, Share of Recipe, Main Recipe, and Production BOM. Assists in providing the automated calculation of the optimal quantity per unit of measure (see Calculation Unit of Measure). |

| Variant Code | Indicates the number of the item variant if variant item is selected for a component. Used with Type = Item or Share of Recipe. You must choose a variant if the Variant Mandatory if Exists field is set to Yes or Default (Yes) in the Item Card; otherwise you will not be able to certify the production structure. |

| Length | Indicates the length of the component. Length is used as a dimension as followed: Quantity = Quantity per x Length. Used with Type = Item, Share of Recipe, Main Recipe, and Production BOM. |

| Width | Indicates the width of the component. Width is used as a dimension combined with length as followed: Quantity = Quantity per x Length x Width. Used with Type = Item, Share of Recipe, Main Recipe, and Production BOM. |

| Weight | Indicates the weight of component. Weight is used as a dimension as followed: Quantity = Quantity per x Weight. Used with Type = Item, Share of Recipe, Main Recipe, and Production BOM. |

| Depth | Indicates the depth of component. Depth is used as a dimension combined with length and width as followed: Quantity = Quantity per x Length x Width x Depth. Used with Type = Item, Share of Recipe, Main Recipe, and Production BOM. |

| Calculation Formula | Determines how the Quantity field is calculated. The options are <Blank>, Length, Length * Width, Length * Width * Depth, Weight, Fixed Quantity, and Recipe. Used with Type = Item, Share of Recipe, Main Recipe, and Production BOM. |

| Substitution Available | Indicated that a substitute is available for the item on the line (see Substitutions). |

| Lead-Time Offset | Specifies the time that is required to assemble or produce the item. The value is copied from the Lead-Time Offset field on the assembly BOM or production BOM. The due date calculation of the production component uses this Lead-Time Offset. Used with Type = Item, Share of Recipe, Main Recipe, and Production BOM. |

| Scrap % | Increases the required quantity for a component in the production order but will not affect any of the other components or the capacity needs for linked operations. Used with Type = Item, Share of Recipe, Main Recipe, and Production BOM. |

| Starting Date | Indicates the first date when the production structure line should be used. Used with Type = Item, Share of Recipe, Main Recipe, and Production BOM. |

| Ending Date | Indicates the last date when the production structure line should be used. Used with Type = Item, Share of Recipe, Main Recipe, and Production BOM. |

| Position / Position 2 / Position 3 | Specifies more exact if a component has to be placed at a specific position in a production structure therewith a specific order of processing is shown. Used with Type = Item, Share of Recipe, Main Recipe, and Production BOM. |

| Lot Determining | Transfers the lot number of the component to the output product of the production order. The value of this field is transferred from the item which is entered in this line. If the production structure will be certified the value will be copied into the production BOM line. Used with Type = Item and Share of Recipe. For more information, see Lot Determining. |

| Expiration Determining | Identifies all components of a production order that are relevant for calculating the expiration date. It is possible to set or change this setting in the Production Structure, Production BOMs/Recipes, and Prod. Order Components. Used with Type = Item and Share of Recipe. For more information, see Expiration Determining. |

| Comp. Location Code / Comp. Bin Code | Identifies default location- and bin codes that are transferred to the Comp. Location Code and Comp. Bin Code fields on the recipe/production BOM lines if ones are created when the production structure line is certified. These defaults are then transferred to the component lines when a production order is created. For more information, see Production Inbound/Outbound Location Code and Bin Code. NOTE: These fields cannot be edited for Items designated as Type = Non-Inventory. |

| Where-Used Focus | Specifies the column for Production BOMs listed in the Matrix FastTab in the Recipe Comparison Matrix. If this field is assigned to a production structure line then the component will have a column in the matrix. Furthermore, the value of the Where-Used Focus field specifies the sequence for the columns. For example, if Where-Used Focus = 1, then this component will be listed in the first component column, and so on. No component column will be listed if no Where-Used Focus is specified. For more information, see Recipe Comparison Matrix. |

| Setup Time Unit of Meas. Code | Indicates the unit of measure code that manages the setup time. Used with Type = Work Center and Machine Center. |

| Run Time Unit of Meas. Code | Indicates the unit of measure code that manages the run time. Used with Type = Work Center and Machine Center. |

| Wait Time | After an operation is completed, the wait time is the time that an item remains at a work or machine center until you can move it to the next operation. Wait times are times, which occur, for example, due to drying processes or cooling. Used with Type = Work Center and Machine Center. |

| Wait Time Unit of Meas. Code | Indicates the unit of measure code that manages the wait time. Used with Type = Work Center and Machine Center. |

| Move Time | Indicates the time a machine or work center needs to move a process. Used with Type = Work Center and Machine Center. |

| Move Time Unit of Meas. Code | Indicates the unit of measure code that manages the move time. Used with Type = Work Center and Machine Center. |

| Fixed Scrap Quantity | Indicates the quantity to increase gross requirements to account for anticipated loss within the manufacture of a particular product. Transferred from the Machine Center. Used with Type = Work Center and Machine Center. |

| Scrap Factor % | Indicates the scrap factor as a percentage, used to increase gross requirements. It is also used to account for anticipated loss within the manufacture of a particular product. Transferred from the Scrap % field of the Machine Center. Used with Type = Work Center and Machine Center. |

| Lot Size | Indicates the amount of a particular item that is issued as a standard quantity to this production process. Used with Type = Work Center and Machine Center. |

| Minimum Process Time | Indicates the minimum amount of time that is needed to complete an operation. Used with Type = Work Center and Machine Center. |

| Maximum Process Time | Indicates the maximum amount of time that is needed to complete an operation. Used with Type = Work Center and Machine Center. |

| Concurrent Capacities | Indicates the number of machines or persons that are working concurrently. This factor reduces the production lead times of the order. For example: Processing requires a run time of 4 hours. By using two machines, you can halve the run time to 2 hours. Used with Type = Work Center or Machine Center. |

| Send-Ahead Quantity | Indicates the movement of a portion of a lot of material to a subsequent operation before completion of the current operation for all units of the lot. The purpose of sending material ahead is to reduce the manufacturing lead-time. The next operation is started when the send ahead quantity is produced. Use the following formula to calculate the send-ahead quantity: Start of the next operation = setup time + send ahead quantity * run time + wait time + move time + queue time (at next operation). Used with Type = Work Center and Machine Center. |

| Standard Task Code | Indicates the Standard Task Code for the production structure line. For more information, see Comments, Tools, Personnel, and Quality Measures. Used with Type = Work Center and Machine Center. |

| Unit Code per | Indicates the task-related production costs. This value is used in the unit cost calculation. There are two ways to enter calculation rates. If you want to calculate with a uniform calculation rate per capacity, this is saved in the Unit Cost field on the Work Center Card. However, if you want work with different cost rates that depend on the operation, you can control this with the Specific Unit Cost field on the Work Center Card. Used with Type = Work Center and Machine Center. |

| Sequence Planning | Indicates the sequence work center that will be used in Sequence Planning. Only one sequence work center can be selected. Used with Type = Work Center. For more information, see Identify Operation for Sequence Planning. |

| Main Tool | Indicates the tool that will be used in Sequence Planning. Only one tool can be set as main. Used with Type = Tool. |

| Main Insert | Indicates the insert that will be used in Sequence Planning. Only one insert can be set as main. Used with Type = Insert. |

| Min. Value | Indicates a minimum value to be met for informational purposes. This value is transferred to the production order component or operation and can be viewed or changed as needed. Used with Type = Standard Task Quality Measure. |

| Max. Value | Indicates a maximum value to be met for informational purposes. This value is transferred to the production order component or operation and can be viewed or changed as needed. Used with Type = Standard Task Quality Measure. |

| Mean Tolerance | Indicates the acceptable mean tolerance for informational purposes. This value is transferred to the production order component or operation and can be viewed or changed as needed. Used with Type = Standard Task Quality Measure. |

| Required Quantity | Assists in providing the automated calculation of the optimal quantity per unit of measure. Used with Type = Item. For more information, see Calculation Unit of Measure. |

| Allocation Quantity | Assists in providing the automated calculation of the optimal quantity per unit of measure. Used with Type = Item. For more information, see Calculation Unit of Measure. |

| Alloc. Unit of Measure Code | Assists in providing the automated calculation of the optimal quantity per unit of measure. Used with Type = Item. For more information, see Calculation Unit of Measure. |

| Parallel Operation Code | Combines routings that are the next or previous in the Production Structure line. Used with Type = Work Center and Machine Center. For more information, see Parallel Operations. |

| Enclosure | Used with the integration of COSMO Discrete Manufacturing (see Integration of COSMO Discrete Manufacturing). |

| Enclosure Drop Shipment | Used with the integration of COSMO Discrete Manufacturing (see Integration of COSMO Discrete Manufacturing). |

| Description 2 - 5 | Additional description fields, each holds up to 50 characters. |

| Production BOM Exists | Indicates if a production BOM exists for the item on the selected production structure line. Used with Type = Item and Share of Recipe. |

| Routing Exists | Indicates if a routing exists for the item on the selected production structure line. Used with Type = Item and Share of Recipe. |

When the production structure is certified – depending on the sequence of entry – links are added between the routing and production BOM using connection codes.

Note

If you have the integration with Advanced Manufacturing Suite, fields relating to COSMO Quality Assurance are also on the production structure line. For more information, see Production Structure Lines.

Functions Menu

On the Lines FastTab, choose the Functions menu to access actions relating to the matrix lines.

Cut

This action enables individual lines or multiple lines from the same or a different production structures to be cut and copied to the clipboard. When pasting to the new line(s), a message opens asking to confirm the deletion of the source (cut) line(s). If you choose No, then the line is copied and the source line is not deleted.

Copy

This action enables individual lines or multiple lines from the same or a different production structures to be copied to the clipboard.

Paste

This action enables individual lines or multiple lines that were copied to the clipboard from the same or a different production structures to be inserted to the selected line. Pasted lines are not verified and may an generate an error on certification.

Line Menu

On the Lines FastTab, choose the Line menu to access actions relating to the matrix lines.

Substitutions

This action displays item substitutions for the selected production structure line. Item substitutions are only available when the line Type is set to Item or Share of Recipe.

The Item Substitution Entry page can also be opened from the item card. The corresponding item substitutions that are entered here are not only valid for the production process line but also for the entire item.

Use the Personalize function on the production structure lines to display the Substitution Available field for better visibility. If necessary, items can also be exchanged in the component lines in a production order.

Item Routing

This action displays the routing for the item on the selected production structure line, if one exists. Use the Personalize function on the production structure lines to display the Routing Exists field for better visibility.

Item Prod. BOM

This action displays the production BOM for the item on the selected production structure line, if one exists. Use the Personalize function on the production structure lines to display the Production BOM Exists field for better visibility.

Search by Mfg. Dimensions

This action opens the Search by Mfg. Dimensions page, where you can search for Items, Share of Recipe, Work Center, Tools, and Inserts that can then be inserted into the Production Structure lines.

To insert a selection from the Search by Mfg. Dimensions page, select an empty line in the Production Structure and enter the relevant value in the Type field (for example, Item or Share of Recipe). On the Lines FastTab, choose Line > Search by Mfg. Dimensions. In the General section, enter the search criteria and then choose the Find action.

Select the item, work center, tool, or insert from the Mfg. Dimension Search Results FastTab and then choose the OK button. The selected result is added to the Production Structure line.

Note

An existing production structure line will be overwritten with the selected result if a new line is not inserted first.

For more information, see Search by Manufacturing Dimensions.

Ingredients

This action opens the Prod. Structure Line Ingredients page, which displays the calculated quantities for ingredients on a production structure line (see Production Structure Component Ingredients).

Create Item

This action allows you to create a new item with the information from the production structure line, including ingredients and line texts. This function can be used only with production structure lines that have no item number.

The Create Item function uses the standard Microsoft Dynamics 365 Business Central item template feature. Therefore, when this action is run, the Select a template for a new item page will open and when a template is selected, a new Item Card will be created. This new item will include all data from the template.

Paste BOM

This action pastes copied Document BOM lines into the production structure lines. Used with the integration of COSMO Discrete Manufacturing (see Copy Document BOM Line to Production Structure).

Skill Sets

This action opens the Production Structure Skill Sets page where manufacturing skills added to a work center can be viewed or modified. Used with resource scheduling, this action is only accessible on lines with Type = Work Center. For more information, see Resource Scheduling in Production Structures.

Line Texts

If you have the integration with COSMO Text Module in Advanced Manufacturing Suite (AMS), this action is available. For more information, see Line text in production structures, recipes, and routings.

Drawing Set

If you have the integration with COSMO Product Data Management in Advanced Manufacturing Suite (AMS), this action is available. For more information, see Drawings in COSMO Process Manufacturing.

Create Eng. Change Notice

If you have the integration with COSMO Product Data Management in Advanced Manufacturing Suite (AMS), this action is available on the Manufacturing Structure. For more information, see Engineering Change Notices in Production Structures.

Eng. Change Notices

If you have the integration with COSMO Product Data Management in Advanced Manufacturing Suite (AMS), this action is available on the Manufacturing Structure. For more information, see Engineering Change Notices in Production Structures.

FactBox Pane

The FactBox Pane on the right side of the Production Structure page contains links to header, line, item detail, and general notes. The fields in the first three panes are described in the following sections.

Production Structure Details

This FactBox contains the following links:

- Item No. – opens the Item Card page for the item listed in the Item No. field on the General FastTab.

- Items – opens the Items page that displays all items that this Production Structure is attributed. Multiple items can be assigned to a Production Structure, just as multiple production structures can be assigned to an item.

- Prod. Variants – opens the Production Structures page that displays the number of different production variants for the item listed in the Item No. field on the General FastTab.

- Prod. Orders – opens the Prod. Order Line List page that displays the number of ongoing production orders associated with the Production Structure.

- Finsh. Prod. Orders – opens the Prod. Order Line List page that displays the number of Finished Production Orders associated with the Production Structure.

Production Structure Line Details

This FactBox contains the following links:

- Total Share % – displays the share % sum of the lines that are set up with the Share of Recipe type.

- Undefined – displays the share % that is remaining if the total share has not reached 100%.

Production Structure Item Details

This FactBox contains the following links:

- Item No. – opens the Item Card page for the item listed in the Item No. field on the Lines FastTab. Only valid for Item or Share of Recipe line types.

- Availability – displays the current availability of the item listed in the Item No. field on the Lines FastTab. Only valid for Item or Share of Recipe line types.

Item Drawing Set

If you have the integration with Advanced Manufacturing Suite (AMS), the Item Drawing Set FactBox from COSMO Product Data Management is available on the Manufacturing Structure. For more information, see Drawings in COSMO Process Manufacturing.

Line Drawing Set

If you have the integration with Advanced Manufacturing Suite (AMS), the Line Drawing Set FactBox from COSMO Product Data Management is available on Development, Laboratory, and Manufacturing Structures. For more information, see Drawings in COSMO Process Manufacturing.

Action Bar

The actions on the action bar are described in this section.

Show Prod. Order

This action displays production orders that were created from the production structure:

- If only one production order was created, the corresponding production order page opens.

- If multiple production orders were created, a list page opens from which a production order can be opened and viewed.

- If no production orders were created, the following message opens.

Recipe Comparison Matrix

This function allows you to create production structure versions or create new production structures from existing production structures. With this function, you can see the components and make changes to the lines using the history of other production structures (see Recipe Comparison Matrix).

This action generates the Production Structure report for the selected Production Structure.

Calculation

This action opens the Calculations page, displaying all calculations for the production structure. From this page, an existing Calculation Card can be opened or a new calculation can be created (see Integration of COSMO Calculation).

Actions Menu

Choose the Actions menu to access actions relating to the Production Structure lines.

Copy

This action contains two actions for copying existing data to a production structure:

- Prod. BOM / Routing – copies lines from existing production BOM, recipes and routings into the current production structure.

- Production Structure – copies existing production structure to the current production structure.

Create Item

This action allows you to create a new item with the information from the production structure. This function can be used only with the Production Structure Type of Manufacturing Structure that has no item number.

This action uses the standard Microsoft Dynamics 365 Business Central item template feature. Therefore, when the Create Item function is run, the Select a template for a new item page will open and when a template is selected, a new Item Card will be created. This new item will include all data from the template.

Create Prod. Order

This action allows you to create a production order from a production structure. A dialog opens, allowing you to select the production order status.

To create a production order, the production structure must be certified and the Lot Size field must contain a value. If the Production Structure Type field is set to Laboratory Structure, a production order can be created without a production order item (see Research and Development).

Check Recipe

This action performs two tasks prior to certifying the Production Structure:

- Calculates the Share % field if values have been entered in the Shares field.

- Checks if the Share % total equals 100%.

For more information, see Check Recipe.

Recipe Comparison

This action compares two different recipes and recognizes the variations (see Recipe Comparison).

Recipe Search

This action helps you locate recipes. Enter different materials and a range (minimum share % and maximum share %) to search (see Recipe Search).

Production Simulation

This action allows you to simulate the production structure in multiple steps, starting from the item, from which this function is opened. The quantity of the simulation is determined by the batch size (see Production Structure Simulations).

Related Menu

Choose the Related menu to access actions relating to the entire production structure.

Comments

This action displays comments for the selected production structure. Comments are for internal use only; they are not used on any documents.

Work Center Production Rates

This action displays the work center production rates for the work centers on the production structure. Changes made in this page are transferred back to the work center production rates on the item.

Incorporation Items

This action allows you to determine the incorporation items for this production structure (see Incorporation).

By-Production

This action opens the By-Production Lists page, which is used to create and maintain general data for a by-product (see By-Production).

Detail Calc. Standard Cost

This action opens the Detail Calculation page, which displays an overview of the standard cost calculation for the production structure (see Detail Calculations).

Sample Shipment

This action opens the Sample Shipment page, if on the General FastTab, the Sample Shipment toggle is turned on (see Sample Shipment).

Note

Sample shipments are not shipments for which an inventory change is posted. They are neither opened from nor connected to standard Microsoft Dynamics 365 Business Central shipment functions.

Ingredients

This action opens the Prod. Structure Ingredients page, which displays the sum of ingredients that:

- Should be included in the components

- Are included in the entered components

For more information, see Production Structures.

Feedback

Submit feedback for this page .